-

One-Sided Only

Lifting, Mounting, & Bolting -

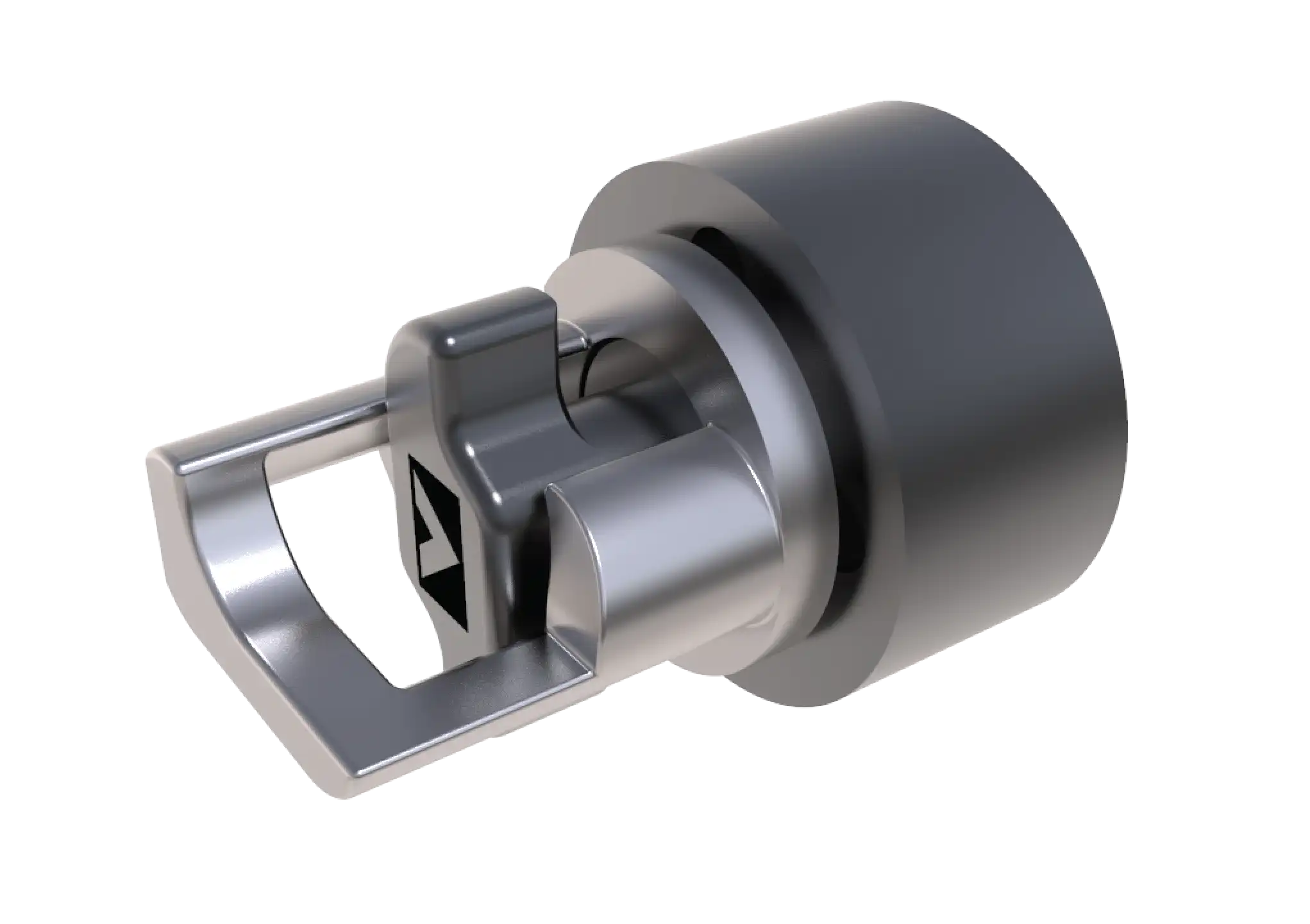

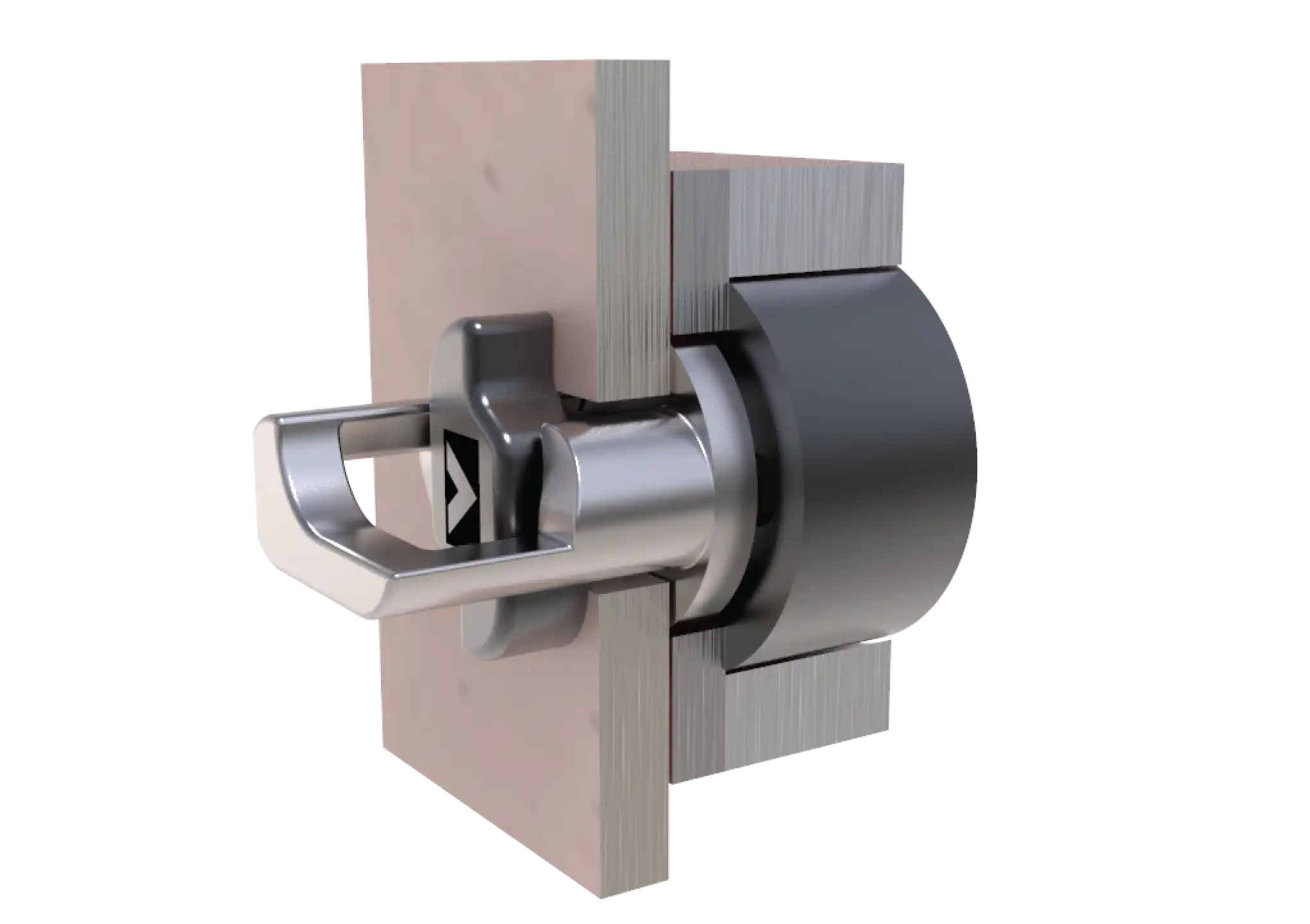

Two-sided Lifting, Mounting & Bolting

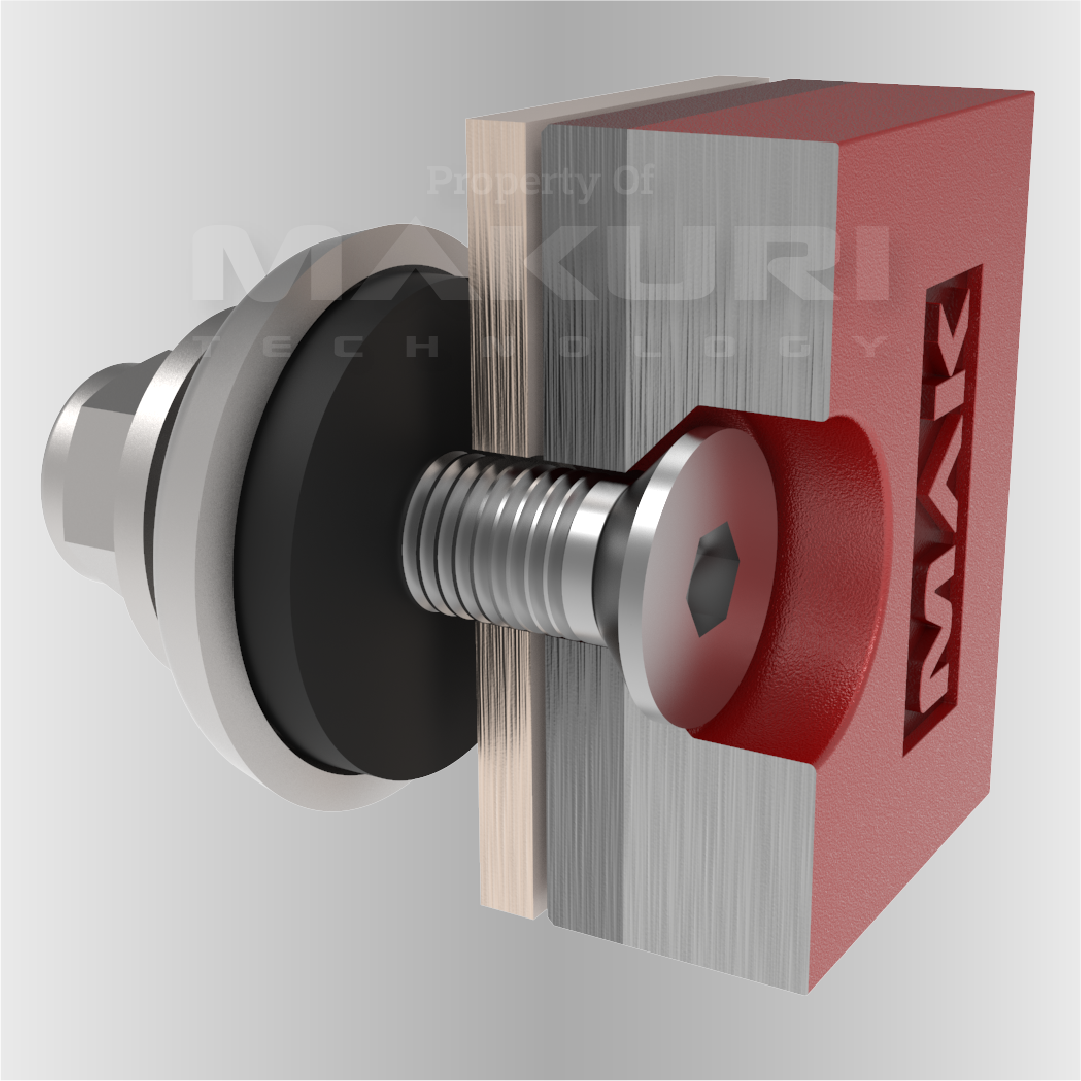

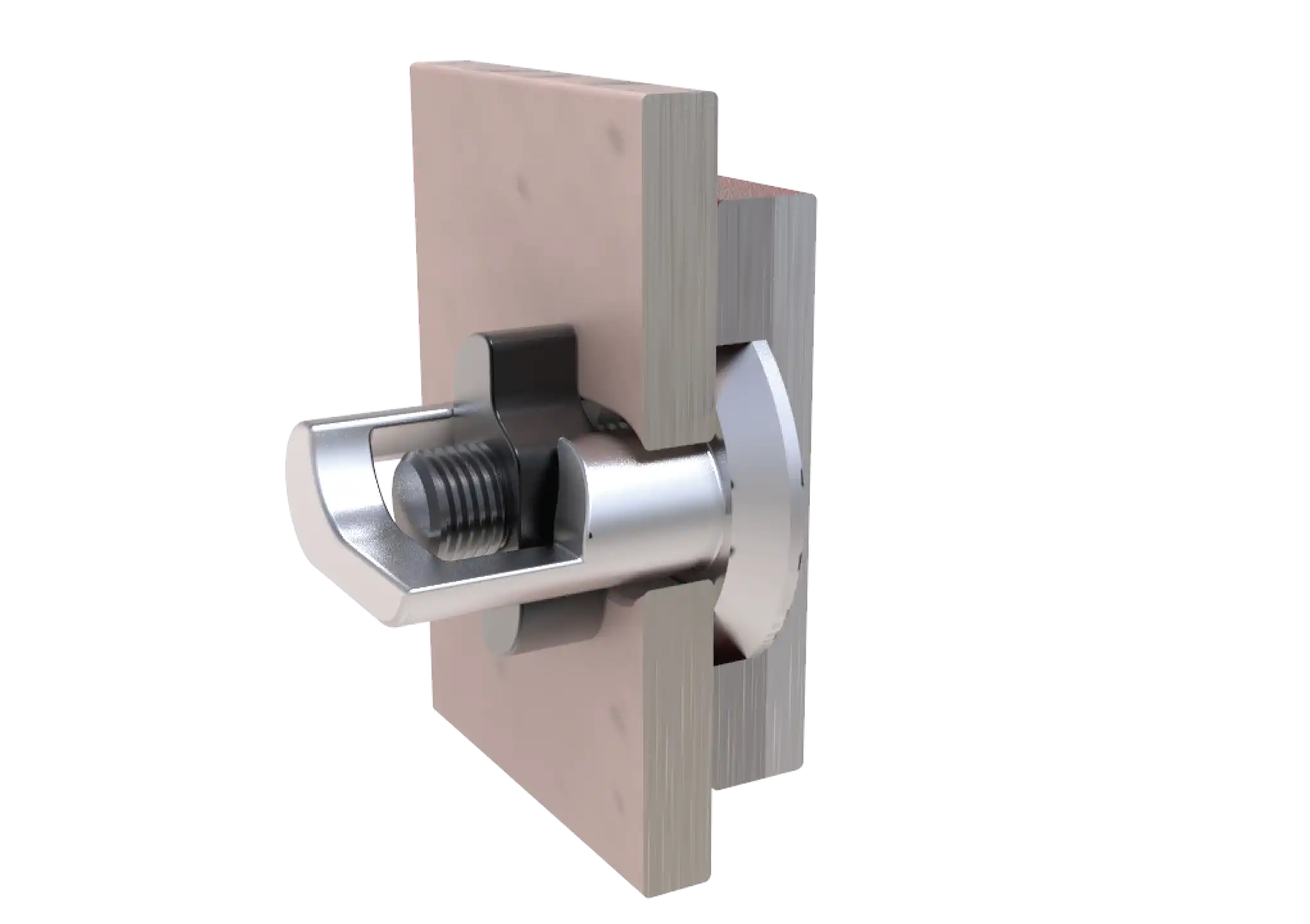

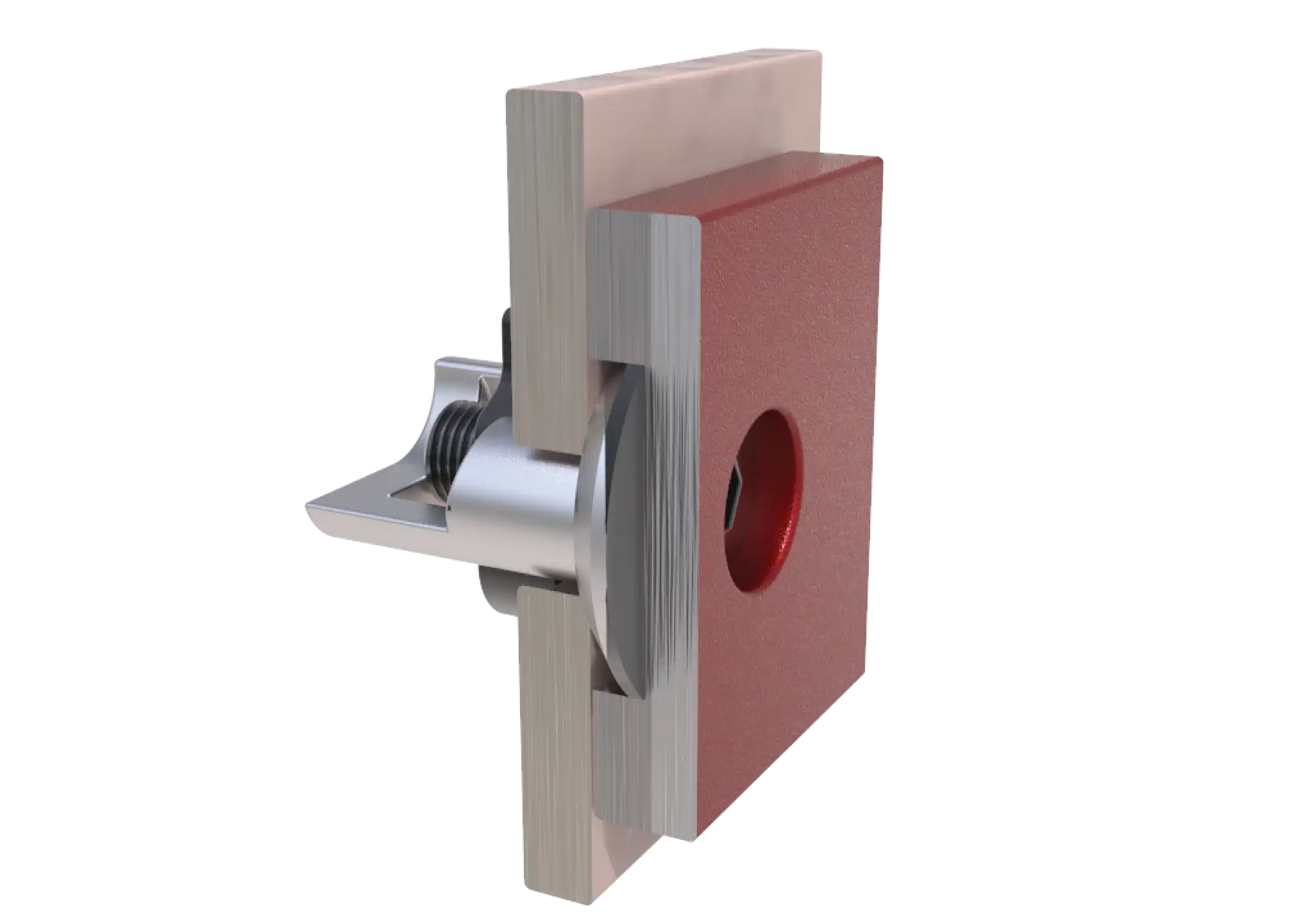

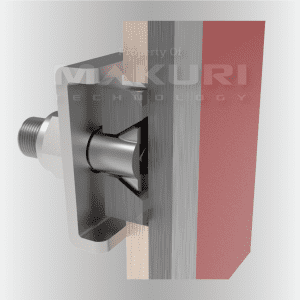

Single Sided Bolting System

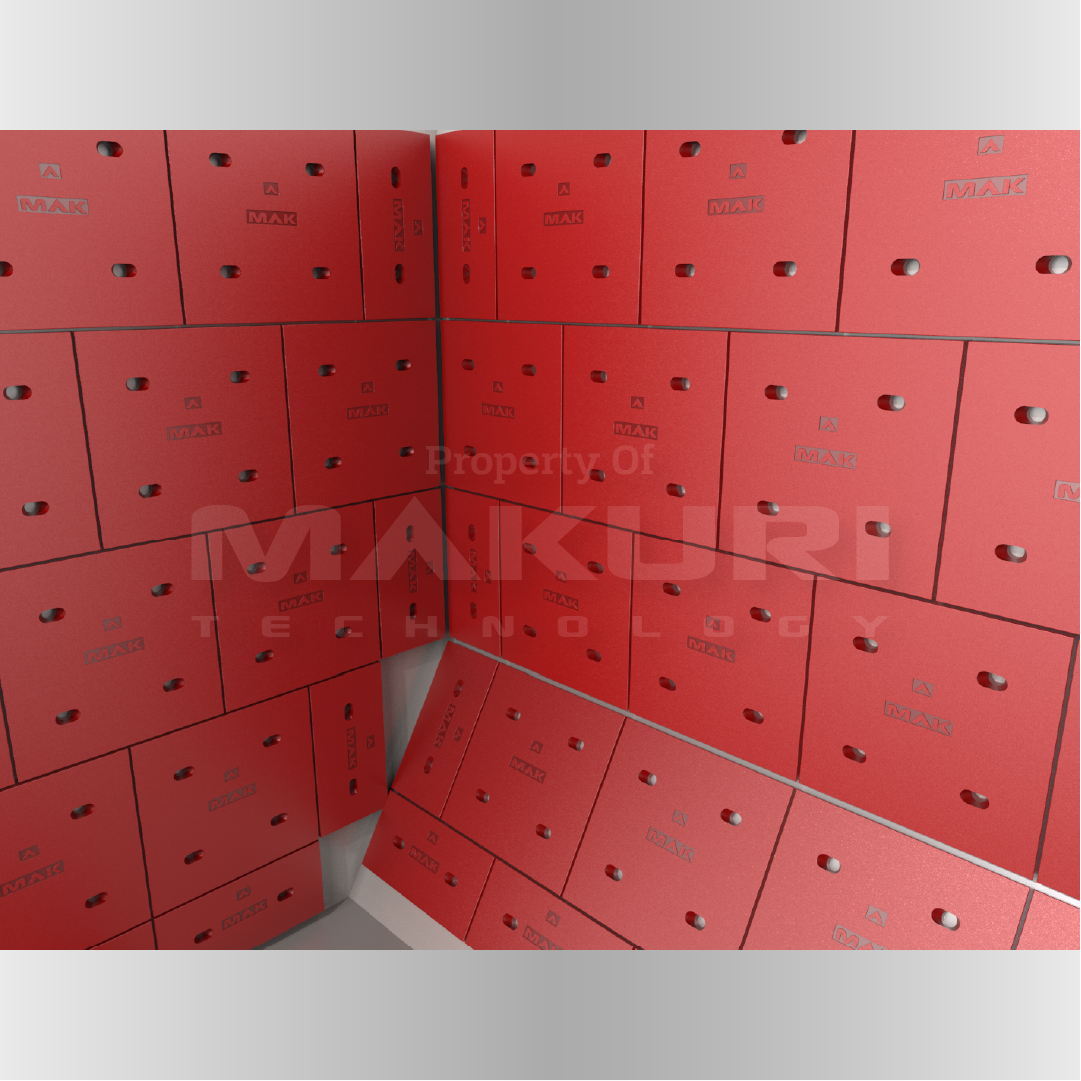

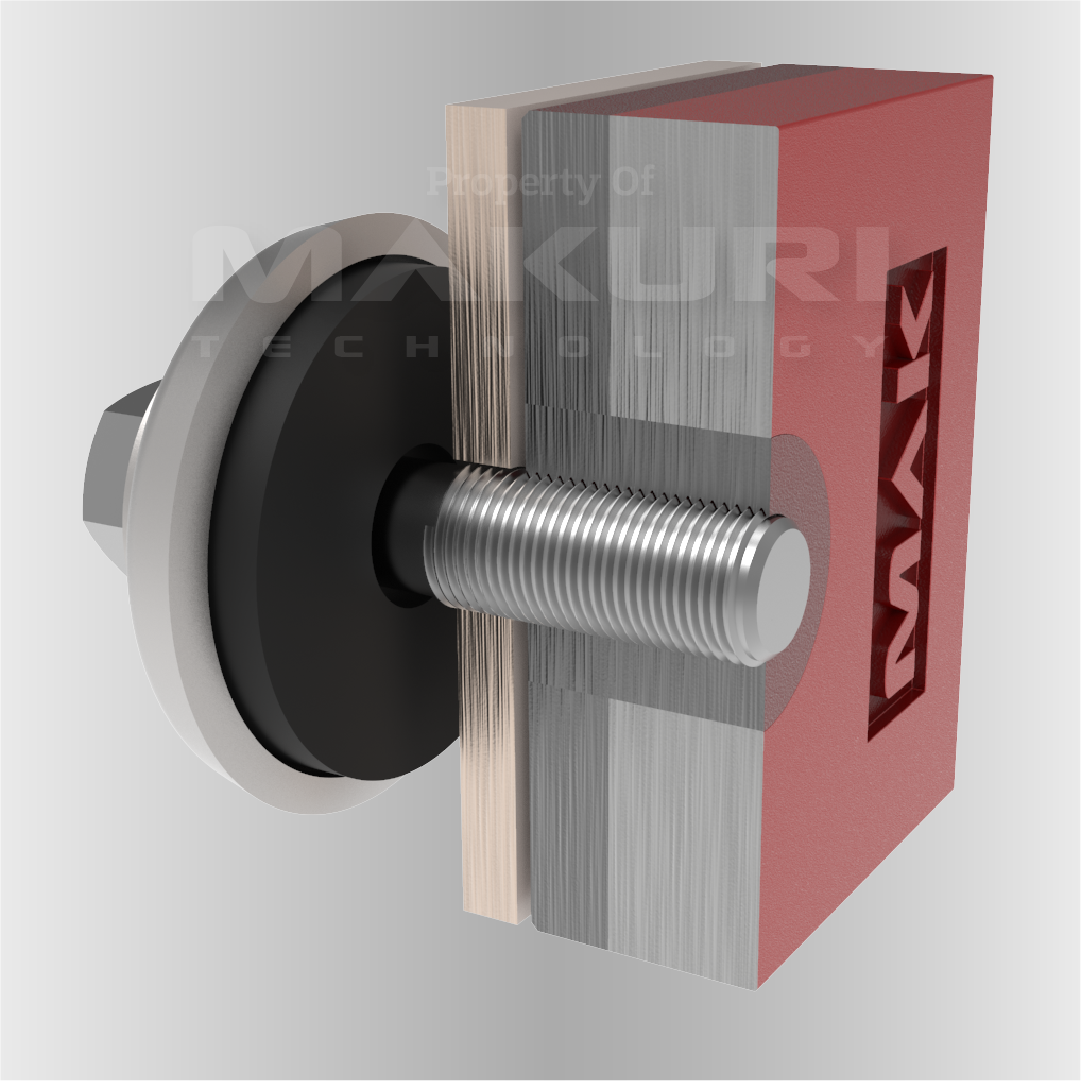

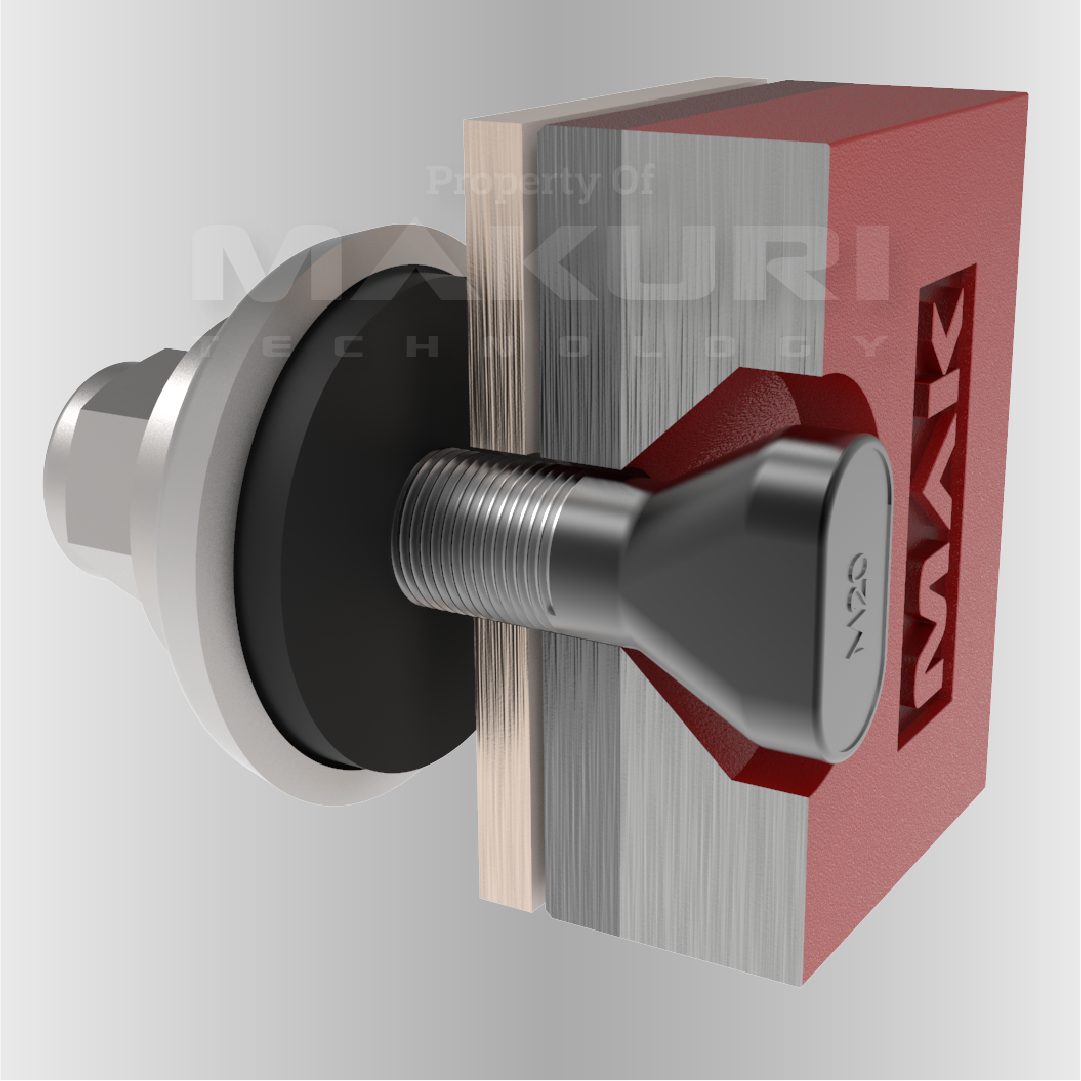

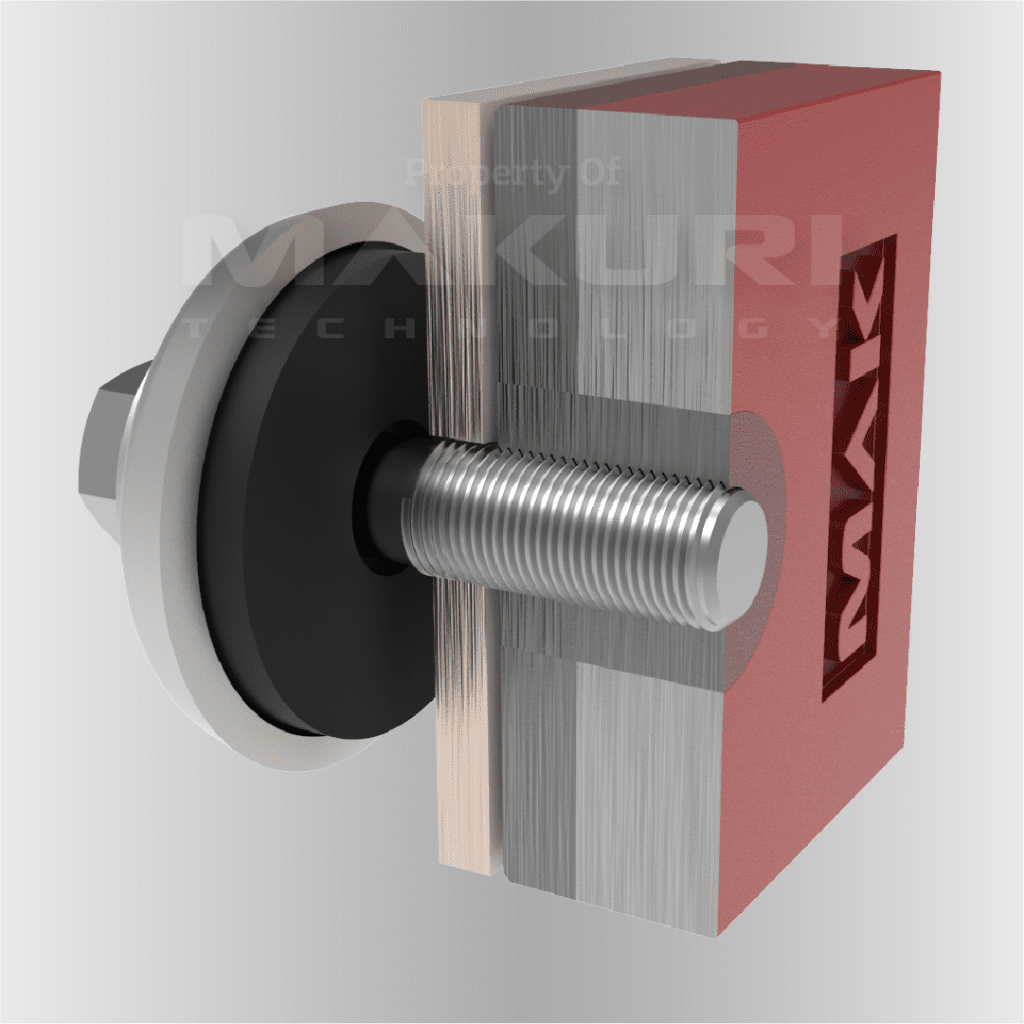

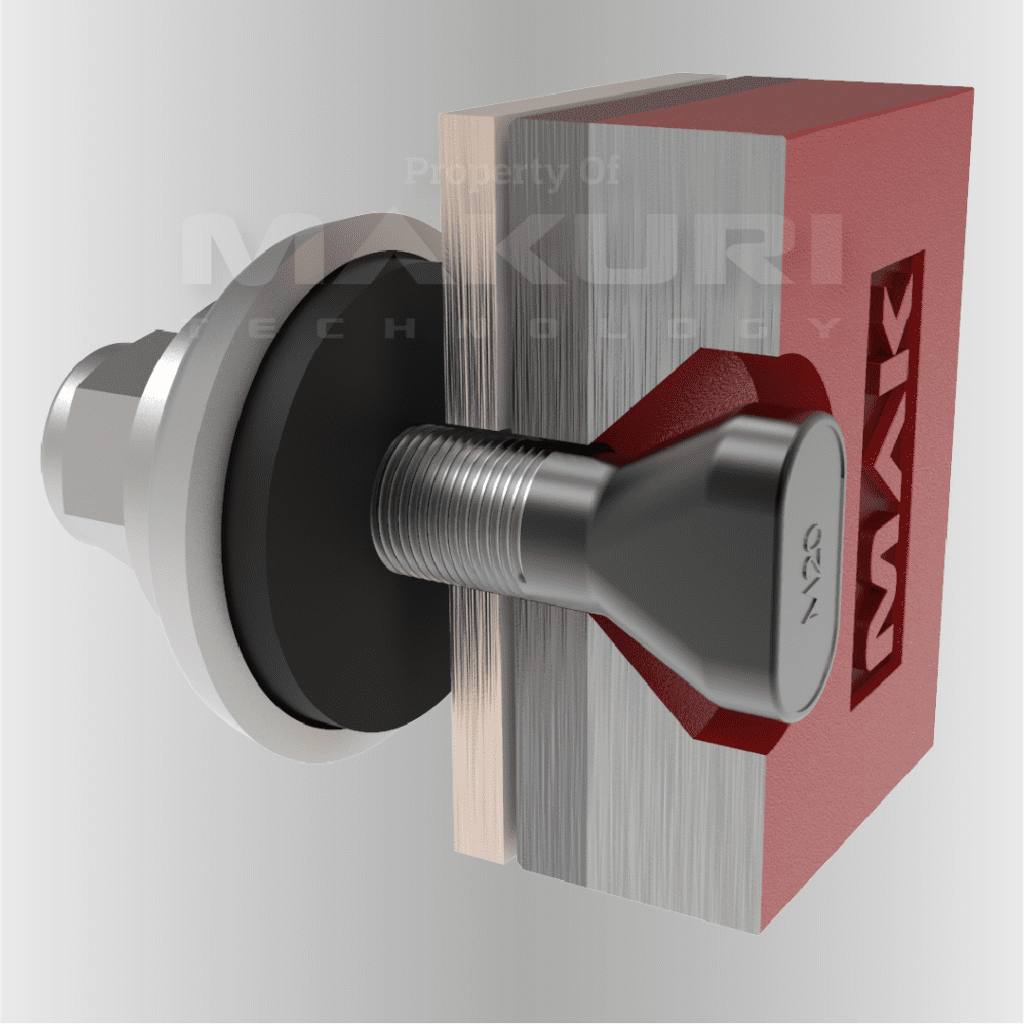

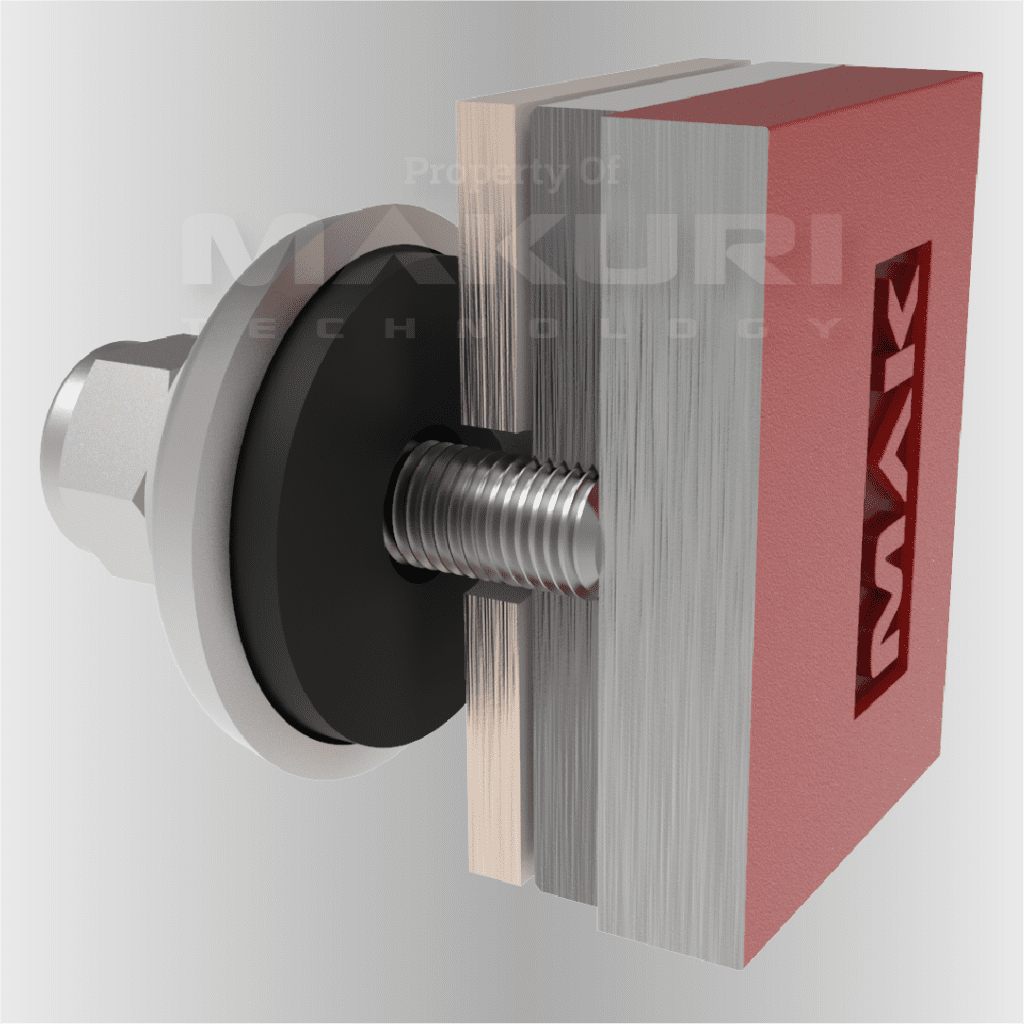

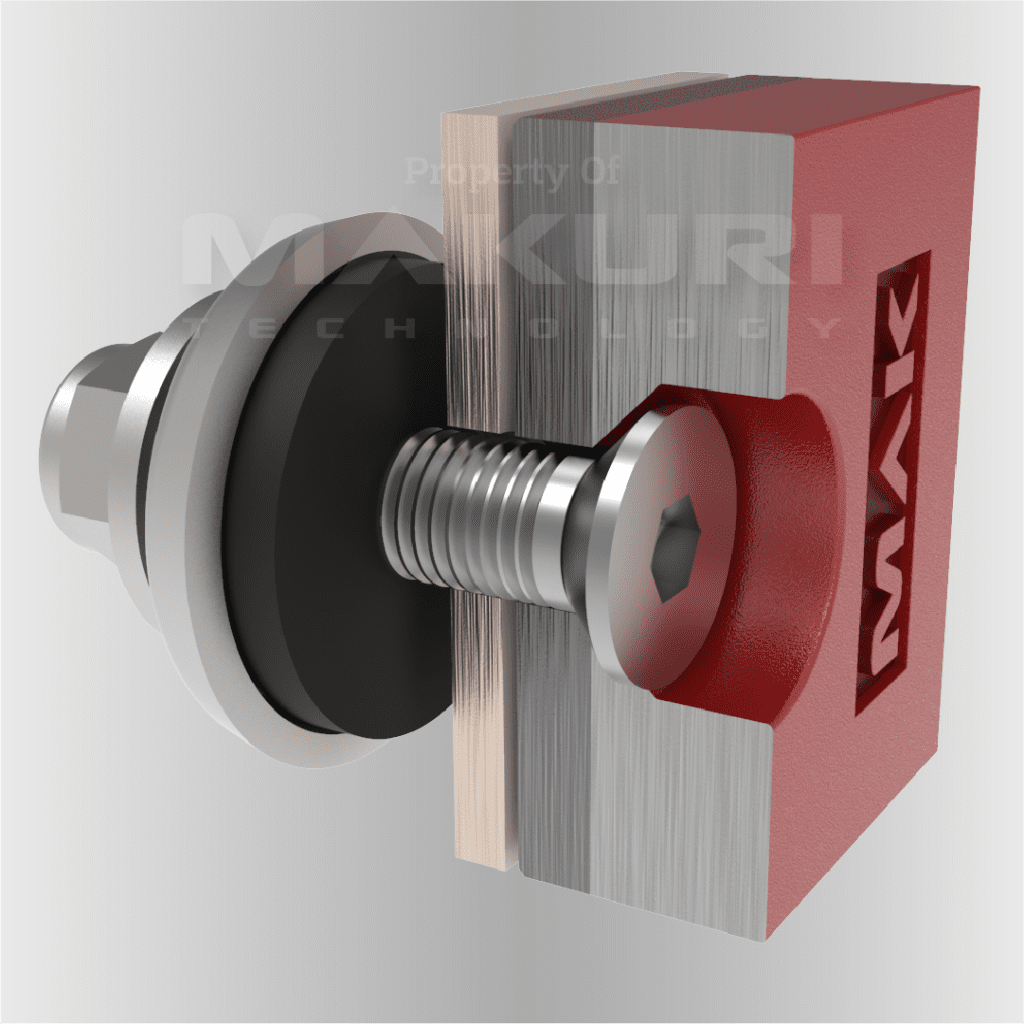

Makuri have progressively developed a true one-sided bolting and installation design called the MAK-Lok system

There is much to be gained by changing to and using faster and safer one-sided mounting systems for all types of chute liners.

The Makuri MAK-Lok system is comprised of 4 major components;

- The nut/bolt

- The mounting plate

- The bolt head receiver – welded into the mounting plate

- The lifting & alignment Tool

MAK-Lok™ Advantages

- The bolt does not require contact with the slotted hole in the chute wall for proper location, so no loss of functionality is encountered if the slots are not perfectly cut.

- The locking element prevents the head of the bolt turning in the hole after installation, dramatically reducing the chance of bolts disengaging

- Bolts on standard T and S style assemblies are pre-fitted with dry threadlocker at the factory. The threadlocker activates when the bolts are tightened, preventing loosening of the nuts during operation

- The wider bolt heads provided on MAK-Lok bolts allows for greater overhang on either side of the slot, further reducing the chance of dislodgement if chute wall slots are in poor condition

- Installation nuts are fitted with through-holes to facilitate removal. The bottom end of the nuts are fitted with nylon inserts to prevent ingress of dirt into the bolt hole.

- Nuts are extended into the backing plate of the wear plate. This ensures that the nut is still able to clamp effectively even with all wear material removed.

- Installation sockets are through hardened and are fitted with replaceable dowels, allowing for replacement on site if breakages occur

- Our rail system allows chutes to be converted to the MAK-Lok system without the need to physically modify the chute.

Two-sided Lifting, Mounting & Bolting

Makuri have progressively developed a range of advanced two-sided bolting and installation systems.

MAK- BB System (Back Bolted)

- Allows for the full life of the liner to be obtained

- Allows for flat packing

- Fast, safe and versatile mounting and lifting options

- Can be used with Makuri’s 5-step installation system

MAK-CB Bolts (Capped Bolts)

- Unique Makuri bimetallic bolts with MAK-Hard white iron caps

- Prevents wear to the structural part of the bolt

- Prevents streaming wear in the bolting hole

- Allows for flat packing

MAK-FT Bolts (Fishtail Bolts)

- Makuri liners can be manufactured to suit any bolt profile

- Fishtail bolts are readily available and do not turn inside the hole

- Allows for some degree of misalignment

- Liners can be flat packed

MAK-HT Studs (High Tensile)

- Provides for simple installation, but requires additional space for packing

- Weld-free design ensures tensile strength of studs is maintained

- Allows for studs to be fully tensioned in critical applications

MAK-CS Bolts (Countersunk)

- Liners can be manufactured to suit any standard CS bolts available on site

- In some applications, use of these can allow the full thickness of wear material to be utilised without damaging the bolt head

- Liners can be flat packed

MAK PW Slots (Plug Weld)

- Can be used where installation conditions do not allow for use of bolts, or where chute conditions are not acceptable for bolting

All bolting options can be supplied with Nyloc nuts, standard hardened washers, self-aligning sealing washers and self-locking washers.