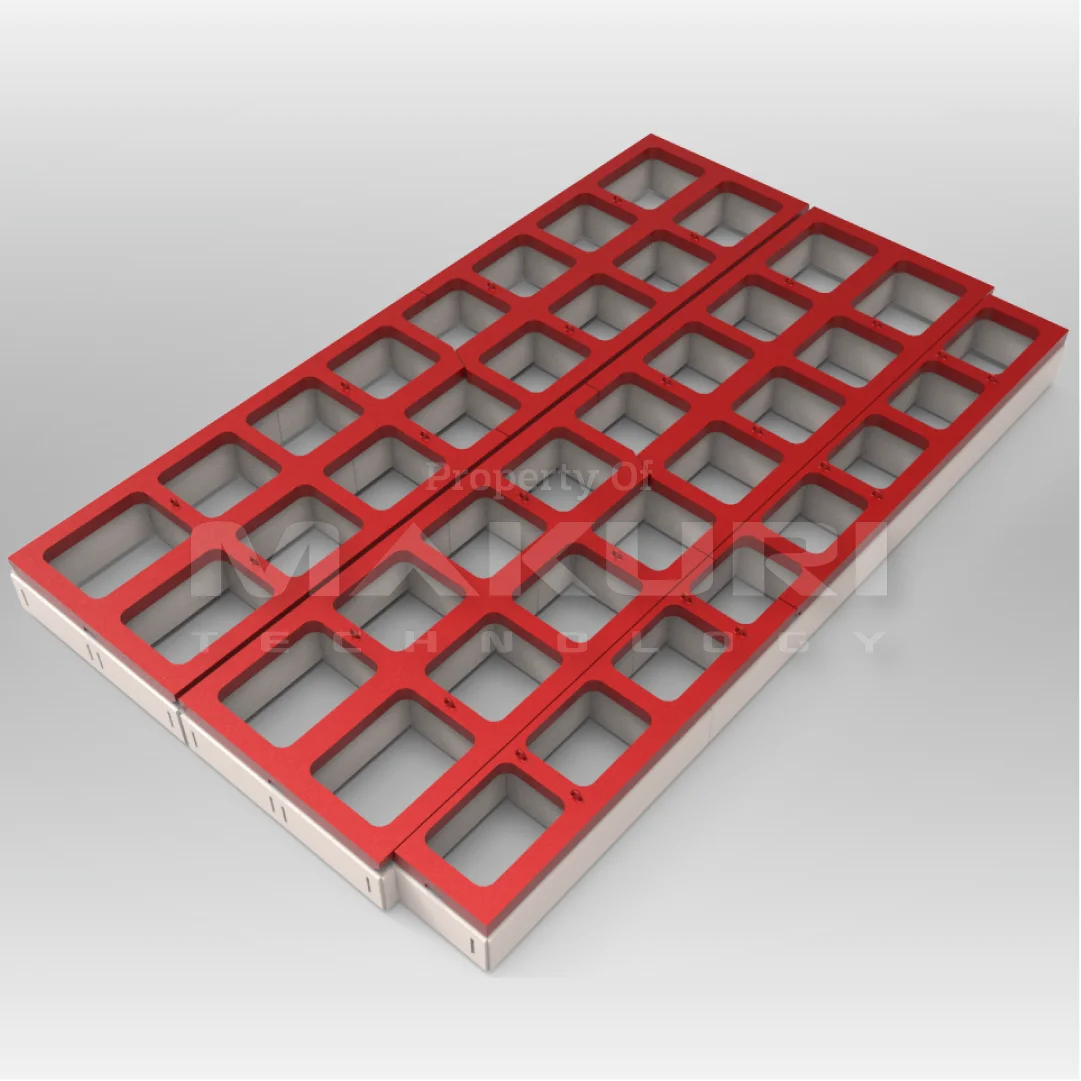

Grizzly Screens

Typical Problems

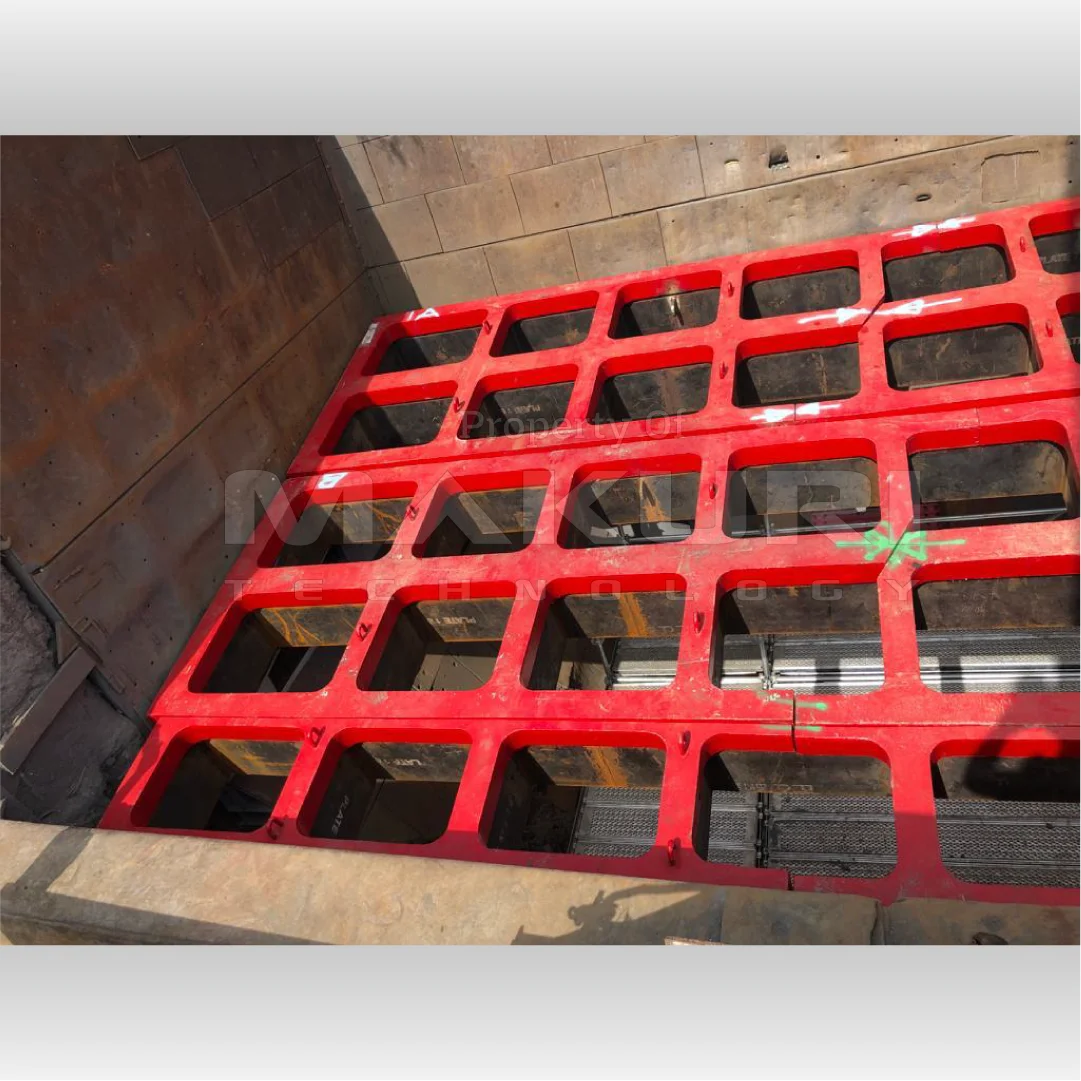

Static grizzly panels

- are easily damaged by dumping impacts, excavator clean up and rock breaker activities

- become easily plugged with oversize material which reduces throughput

- have poor life and performance

- don’t have quick changeable liner systems

- are difficult to access and observe during operation

- are not seen as a priority in many process plants

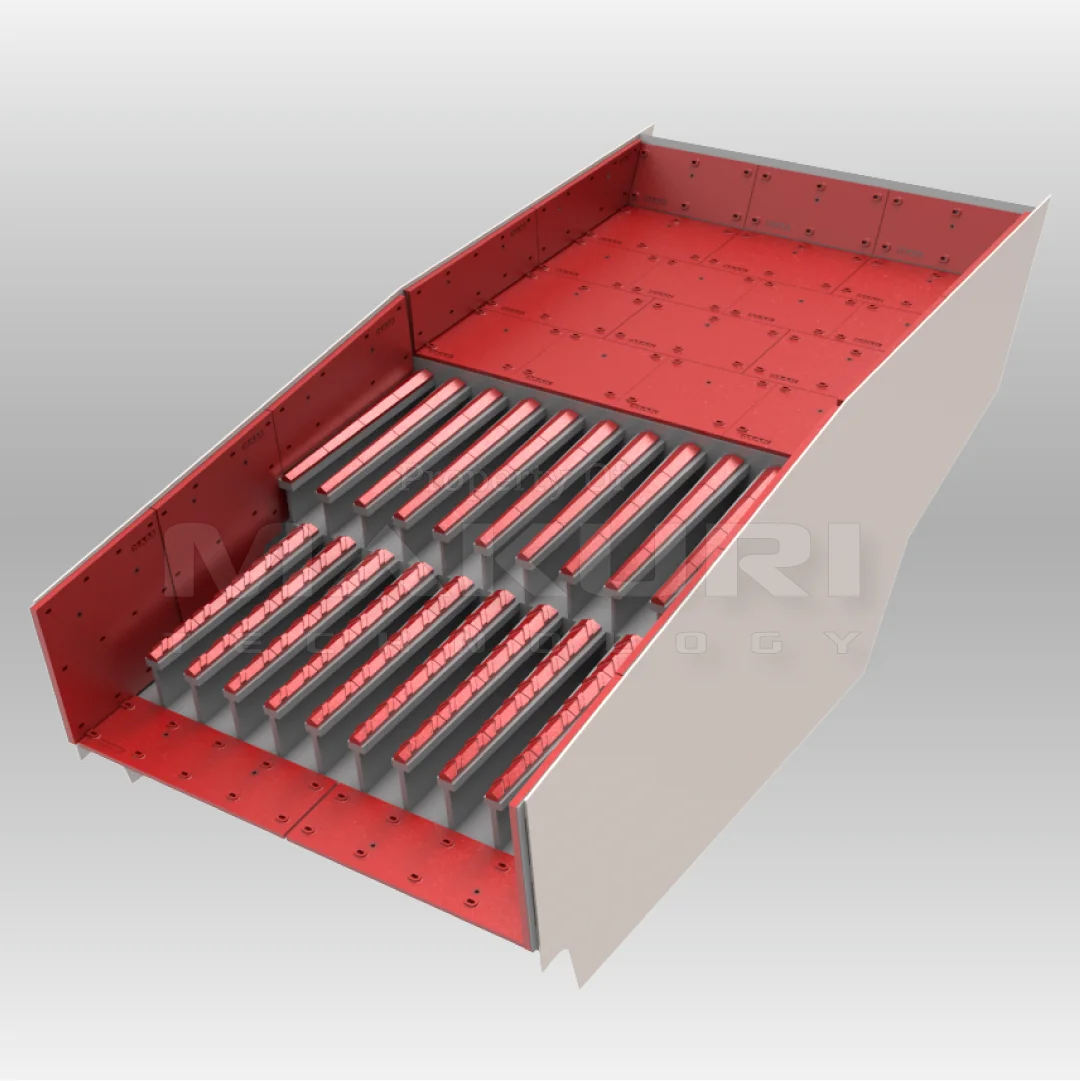

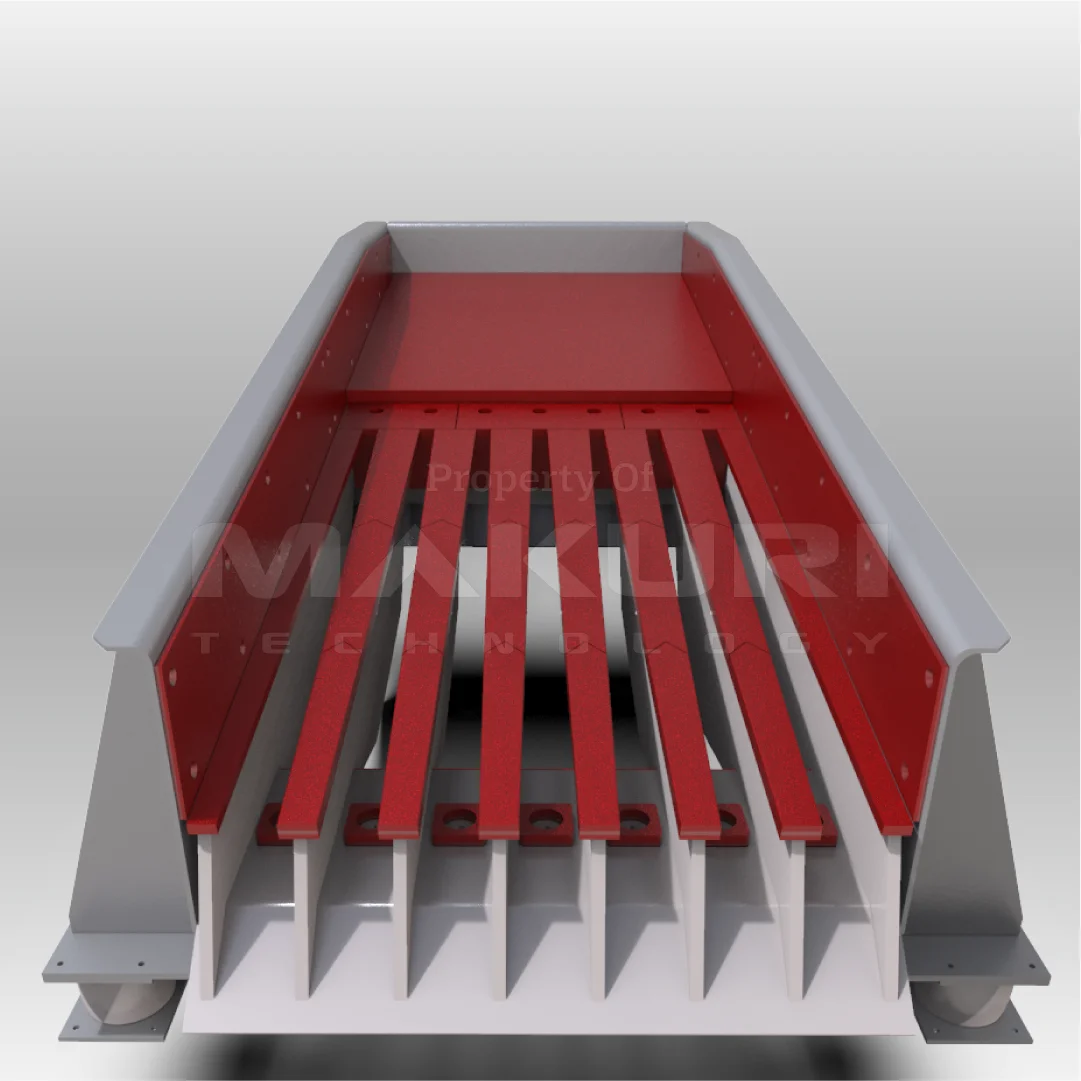

Vibrating grizzly feeders

- Top liner caps wear fast due to extreme abrasion and high impact events

- Poor top cap design and wear profiles result in poor screening efficiency and blockage

- Few to no rotable cartridge designs available by commodity suppliers

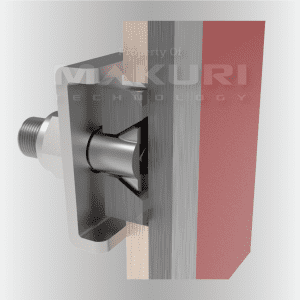

Makuri Solutions

Custom-built designs for longer life and greater screening efficiency

Makuri Technology has chosen to specialise in this area and have developed a number of innovations that address all of the above issues and can greatly extend screen and liner life. These are all covered within the Makuri Intelligent Design™ process

Fully optimised static and vibrating screen designs allow us to guarantee a lower TCO and provide greater sustainability to our industry

We understand plant front end process and wear related issues better than most. Contact us to see how we can optimise your process plant front end to improve overall plant throughput, maximise asset utilisation and lower carbon footprint.