Internal Conveyor Skirting

Typical Problems

- Liners made from low grade Q&T / AR plate

- Life is poor

- No ability to adjust or reverse to extend life

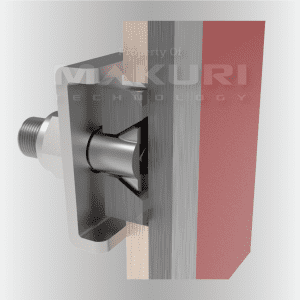

- Excessive clearance under skirt edges causes gouging of the belt and fugitive material

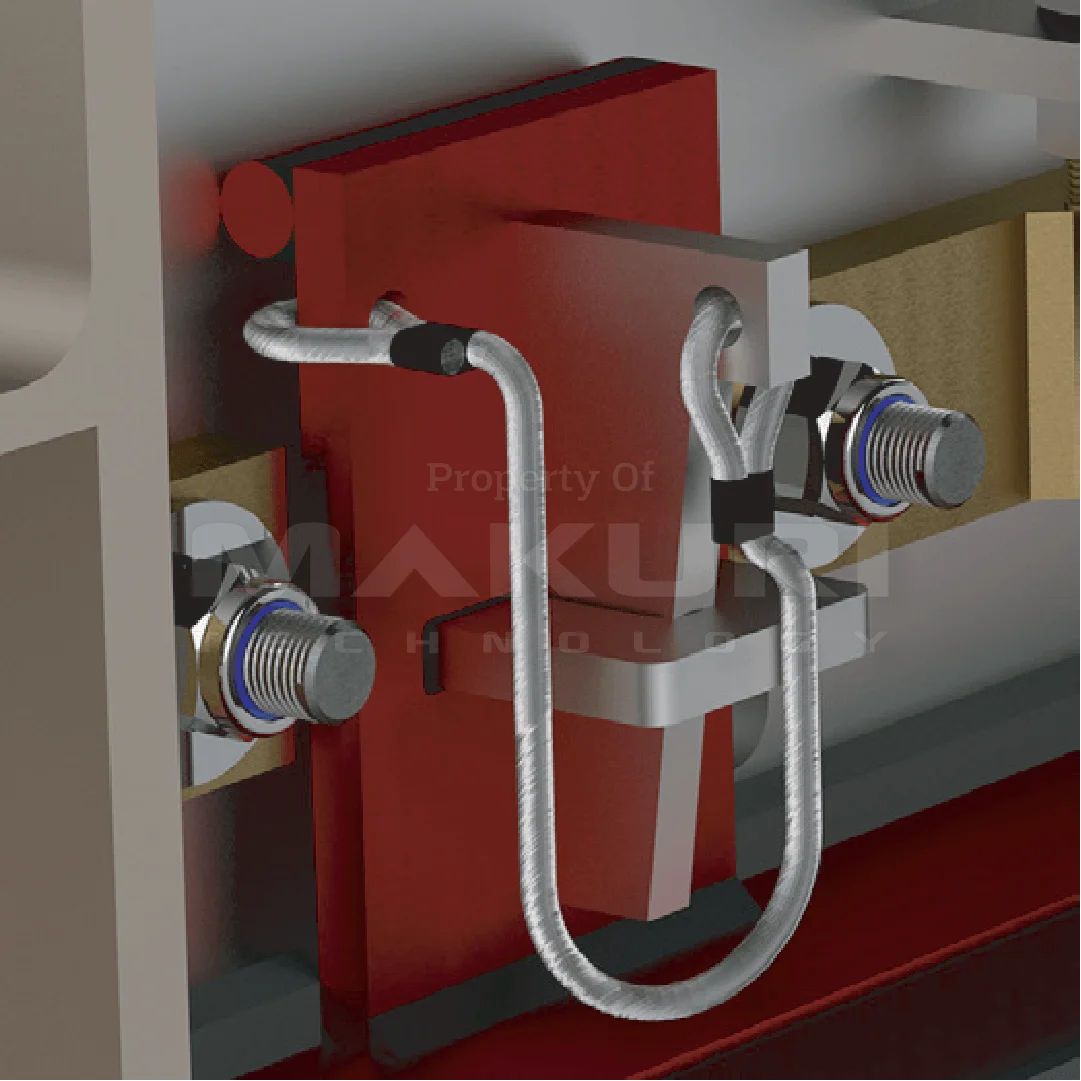

- Most current systems still require personnel on both sides of the chute to fit both liners and bolts correctly

- After bolt heads wear off liners fall out and damage belts and downstream processes

- No online monitoring to predict remaining life of liners and allow for optimised designs

- High risk working environment including confined space and manual handling

Makuri Solutions

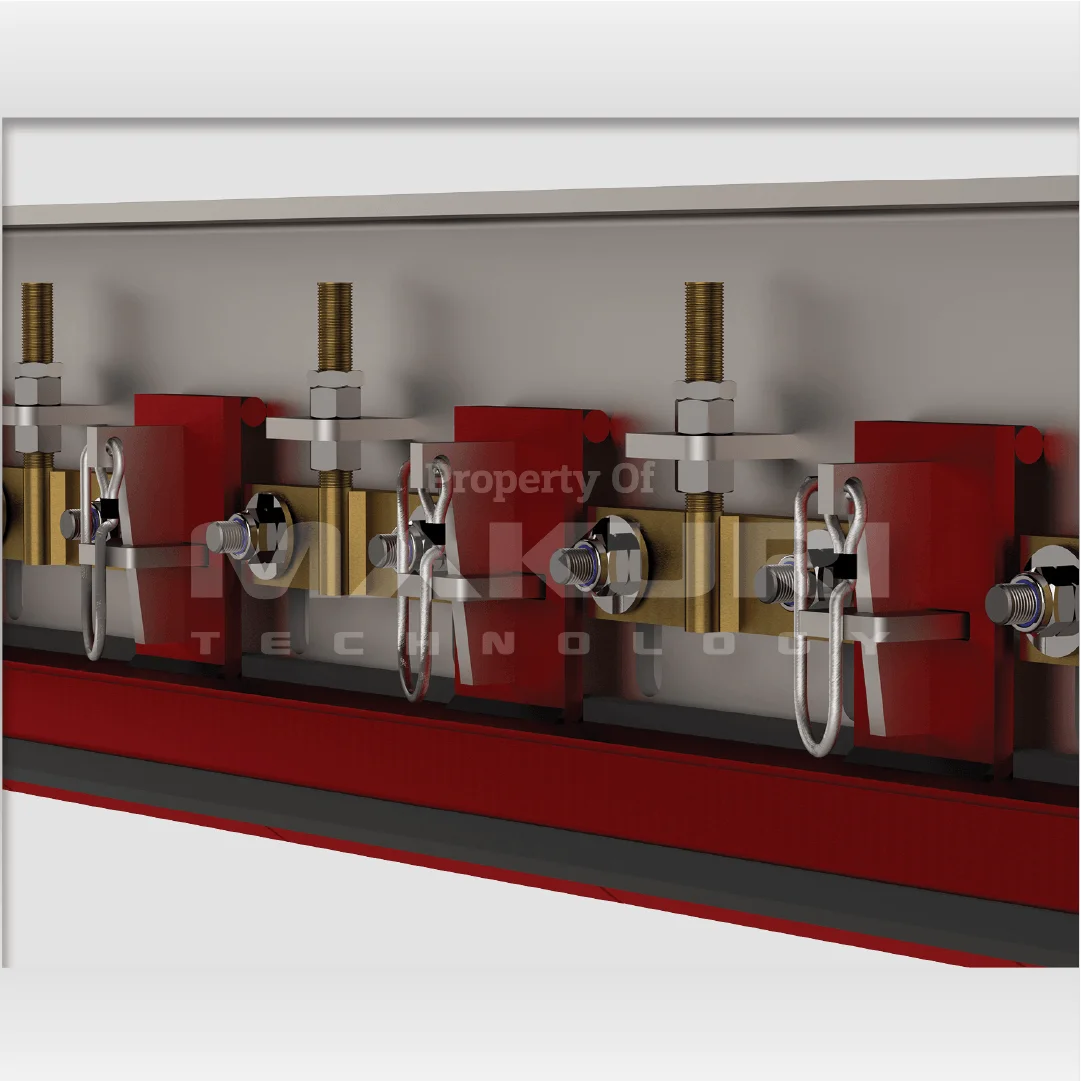

Makuri can supply a wide range of liner designs and mounting options to suit existing site skirting frames and can custom-design additional systems to suit individual requirements.

Makuri technology has chosen to specialise in this are as such we can address all these issues covering Design, Materials, Mounting and Monitoring and are all covered within the Makuri Intelligent Design™ process

Applying the correct internal skirting system allows us to guarantee a lower TCO and provide greater sustainability to our industry

We understand process plant front end maintenance and operational practices better than most. Contact us to see how we can optimise your process plant front end to improve overall plant throughput, maximise asset utilisation and lower carbon footprint