Standard & Custom Wear Liners & Wear Plates – All process plants have a large range of chute wear liner applications and most chutes have no redundancy, so are critical to production. Commodity wear materials based on Q&T / AR Plate, in various lower level hardness grades and thicknesses, still make up the bulk of liner materials used, that are specified at the design phase due to price and convenience. High rates of planned and unplanned downtime are typically experienced in these applications.

Standard & Custom Wear Liners & Wear Plates

Typical Problems

- Tender-stage chute designs using standard/basic liner sizes, mounting systems and materials are used extensively with only initial cost and convenience in mind

- Ongoing process tpoh improvements lead to accelerated wear rates and increased downtime

- Thicker and heavier, but still basic liner materials used to increase life can actually reduce it by restricting material flow and increasing material velocity and/or creating choke points.

- Poor mounting systems require excessive labour to replace and create safety and operational issues if they fall out in service

- The decision as to what type of liners and in what material, thickness and design is often left up to maintenance personnel working only with materials available at hand, whether new or used and no overall optimisation of the chute is undertaken

- No online monitoring to predict the remaining life of liners and allow for optimised designs and materials based on changing wear patterns of individual liners over their life.

- High-risk working environment including confined space, working at heights, hot work and manual handling.

Makuri Solutions

We have the largest range of options available to allow for the absolute best solutions to be had in all chute applications. These include;

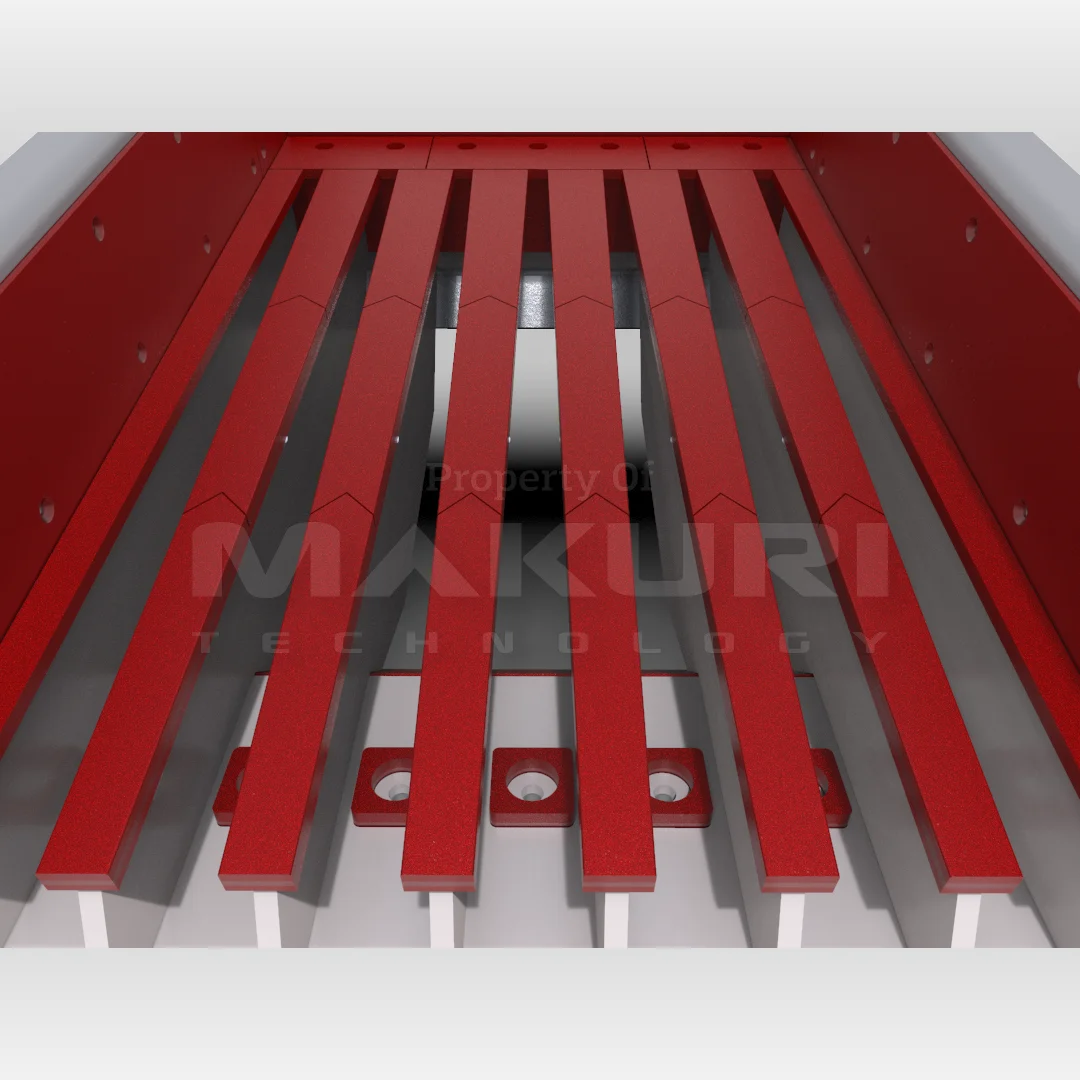

Standard & Custom Liners

- 300×300

- 300×600

- 600×600

- 600×900

- Bolt sizes based on M16 or as designed

- Centre distances based on 75mm edge clearance or as designed

- Custom sizes as designed

- Plus, free* chute liner design service incorporating these and other Makuri chute liner products – see Rock Box, Bund & Lip Liners

* subject to confirmation

Mounting and Installation Options

- Lower labour and safer to install mounting systems

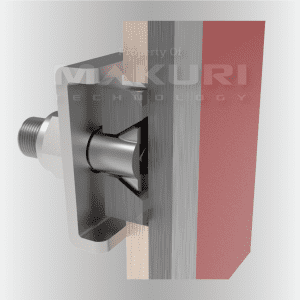

- Our patented one-sided MAK-Lok mounting system c/w integrated lifting and alignment tool

See Liner Mounting Systems

Materials Options & Thicknesses

- Cast steel bonded XAB 1 plates from 10mm (5/5) to 150mm (125/25) or as designed

- XAB 1 can also come with Tungsten, Titanium, or Ceramic inserts in various thicknesses for extreme impact & abrasion applications where significant life increases are required

- Forged steel bonded XAB 8 & 9 plates from 10mm (5/5) to 37mm (25/12)

- Ceramic Bonded plates for both extreme abrasion and highly corrosive applications in various grades and thicknesses as required and with both stud and MAK-Lok mounting options

See Bi-Metallic Wear Plates and Blocks and Ceramic Wear Liners for Chute applications

Wear Monitoring Systems

- Liner plates can come with integrated wear monitoring technology – subject to design confirmation

- Please see our Wear Monitoring technology for more details

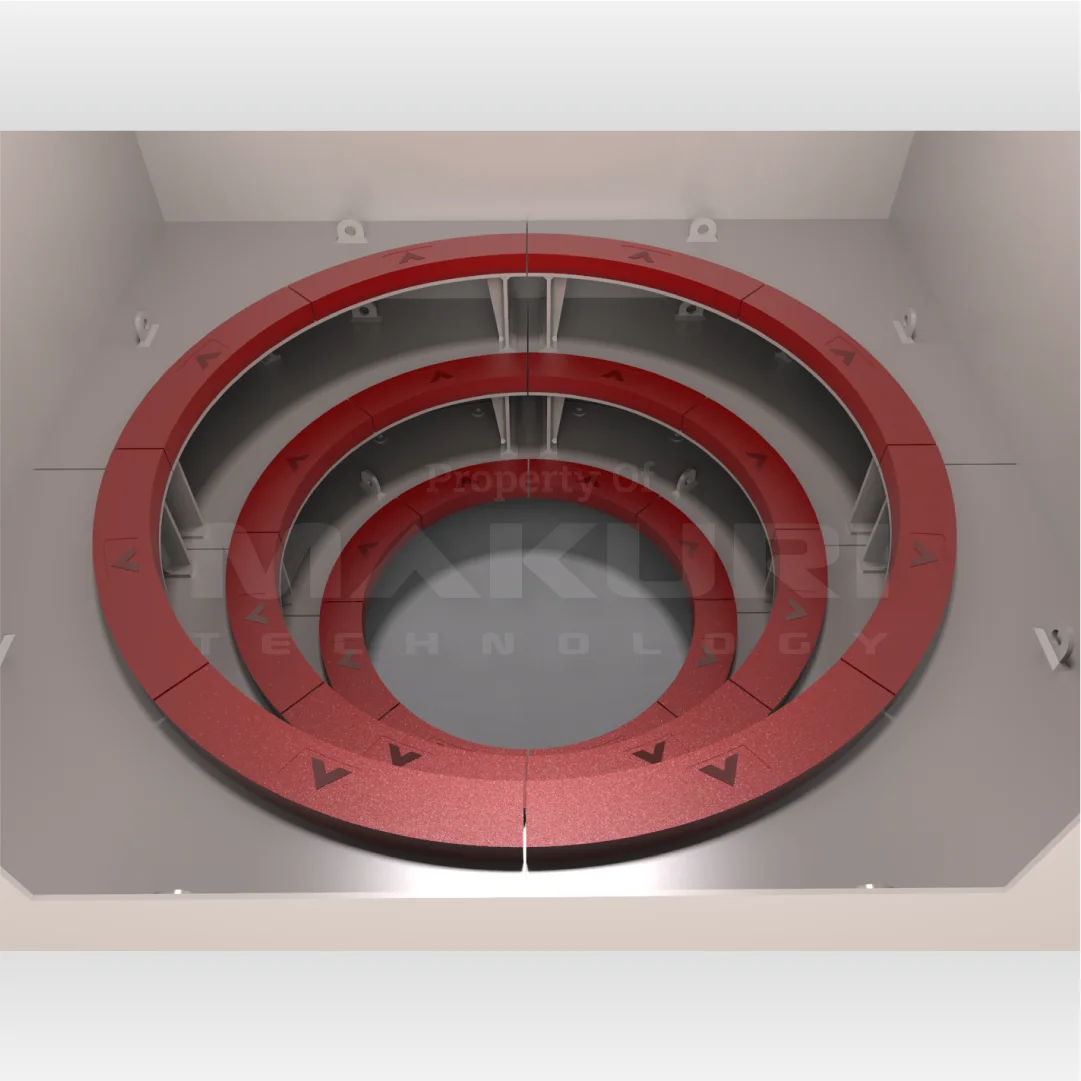

Optimised liners are created for each application by reviewing Design, Materials, Mounting and Monitoring in what we call the Makuri Intelligent Design™ process. This results in integrated solutions that are longer life, lower weight and thickness, have faster and safer mounting methods and come with online monitoring options. Fully optimised chute liners allow us to guarantee a lower TCO and provide greater sustainability to our industry.

We understand process plant front-end bulk material flow and wear better than most. Contact us to see how we can optimise your process plant front end to improve overall plant throughput, maximise asset utilisation and lower carbon footprint.