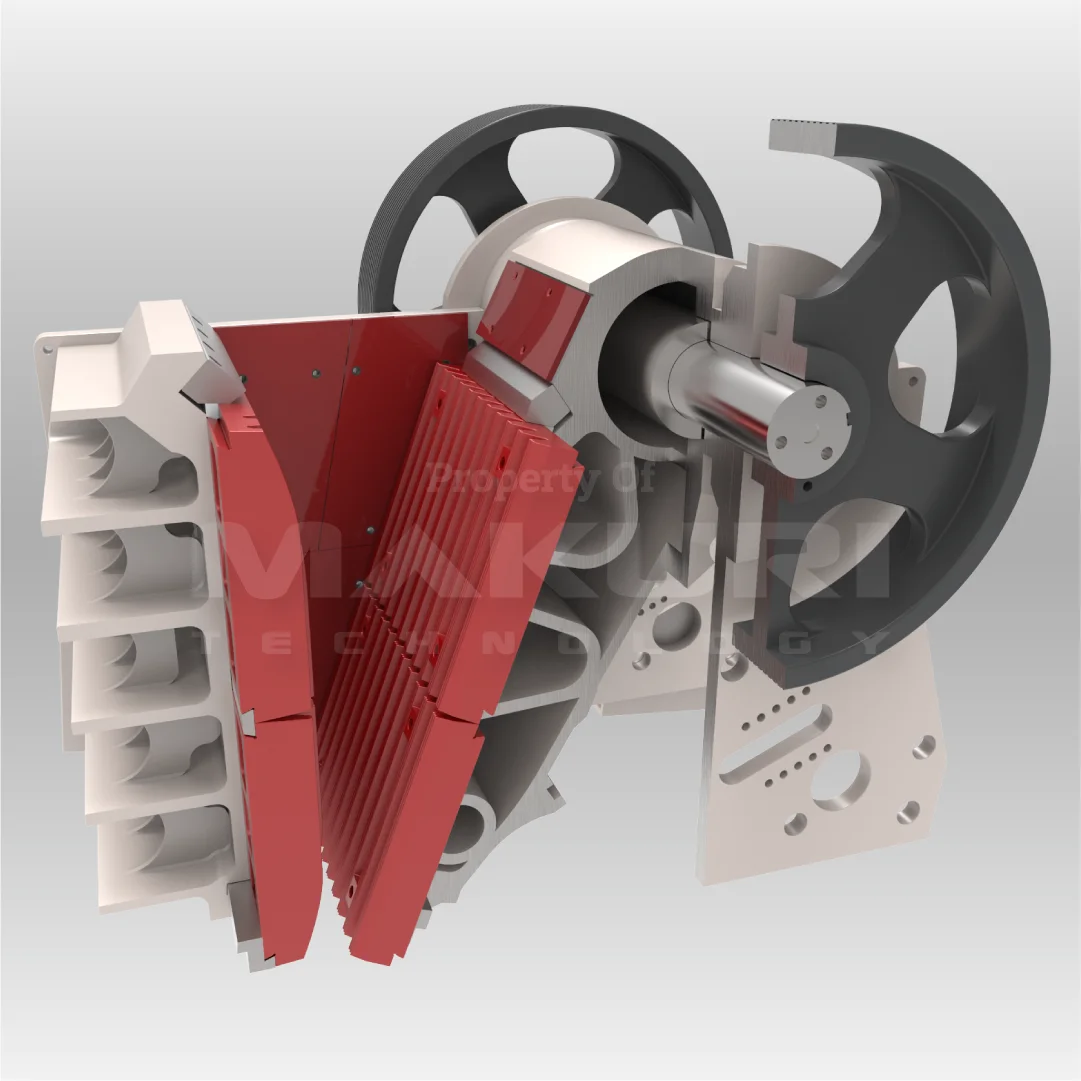

Not boiling material in the cavity when operating at the best CSS, being able to deal with all material shapes, sizes and hardness’s, fully utilising liner material, plus doing safer and less frequent liner changes are the challenges when using a primary jaw crusher.

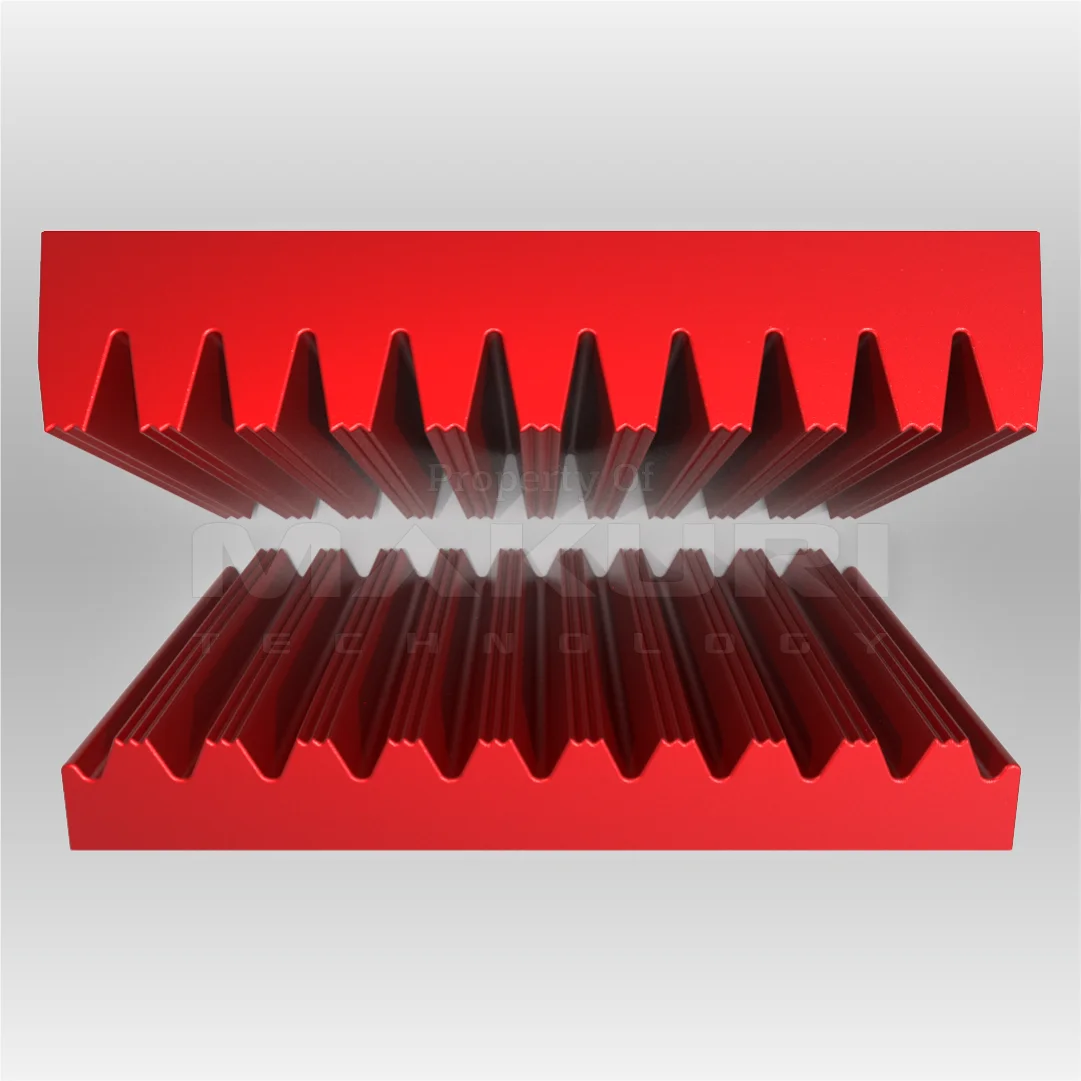

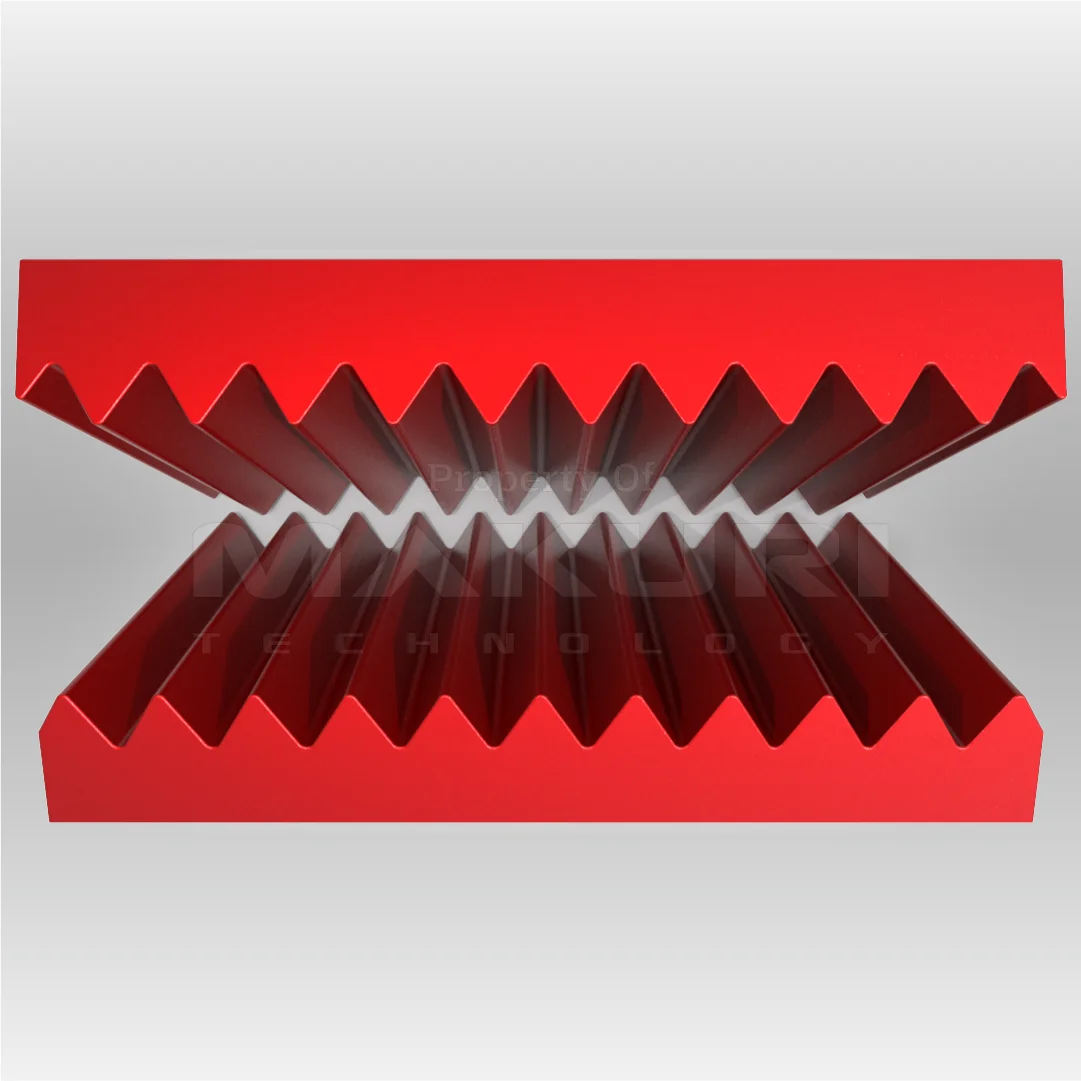

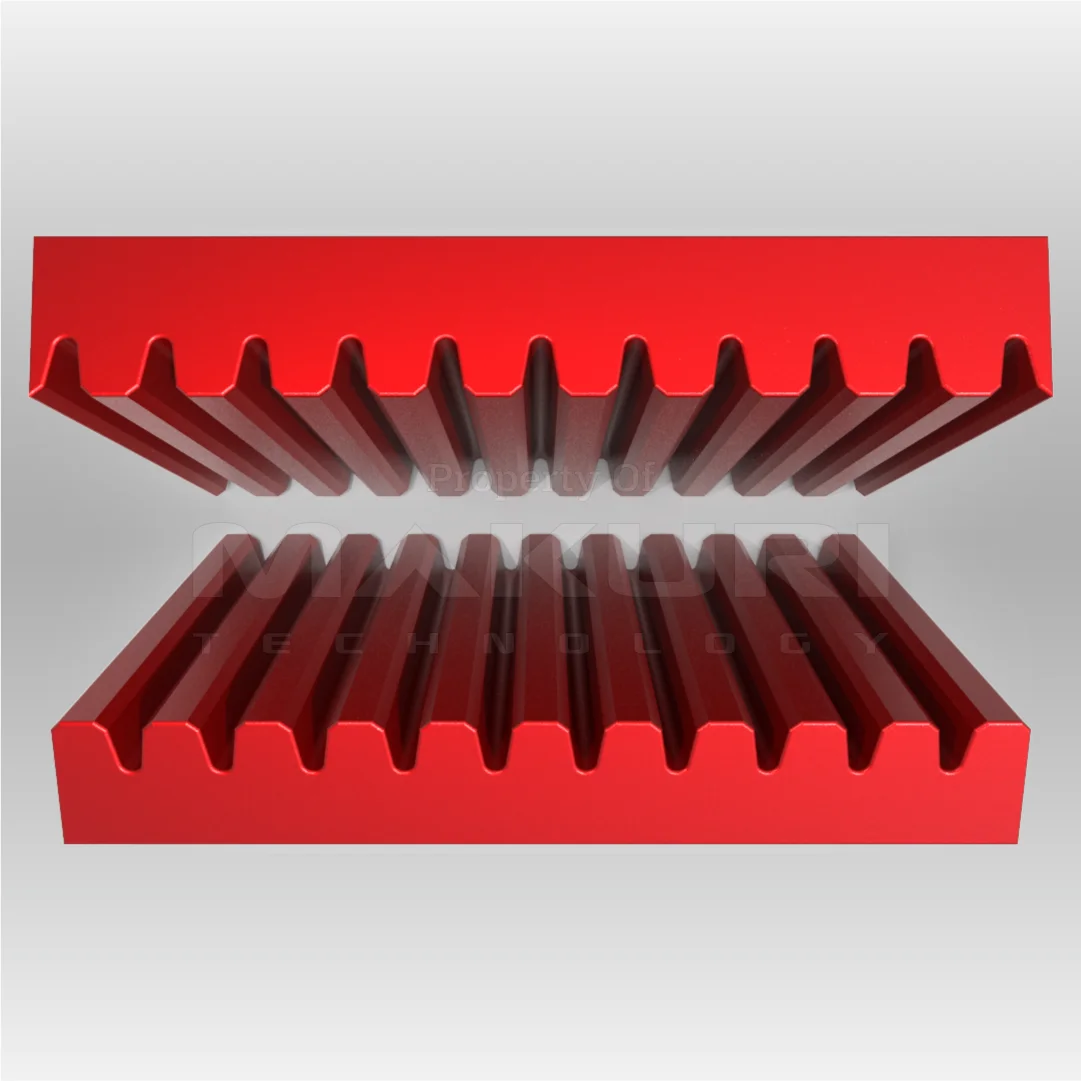

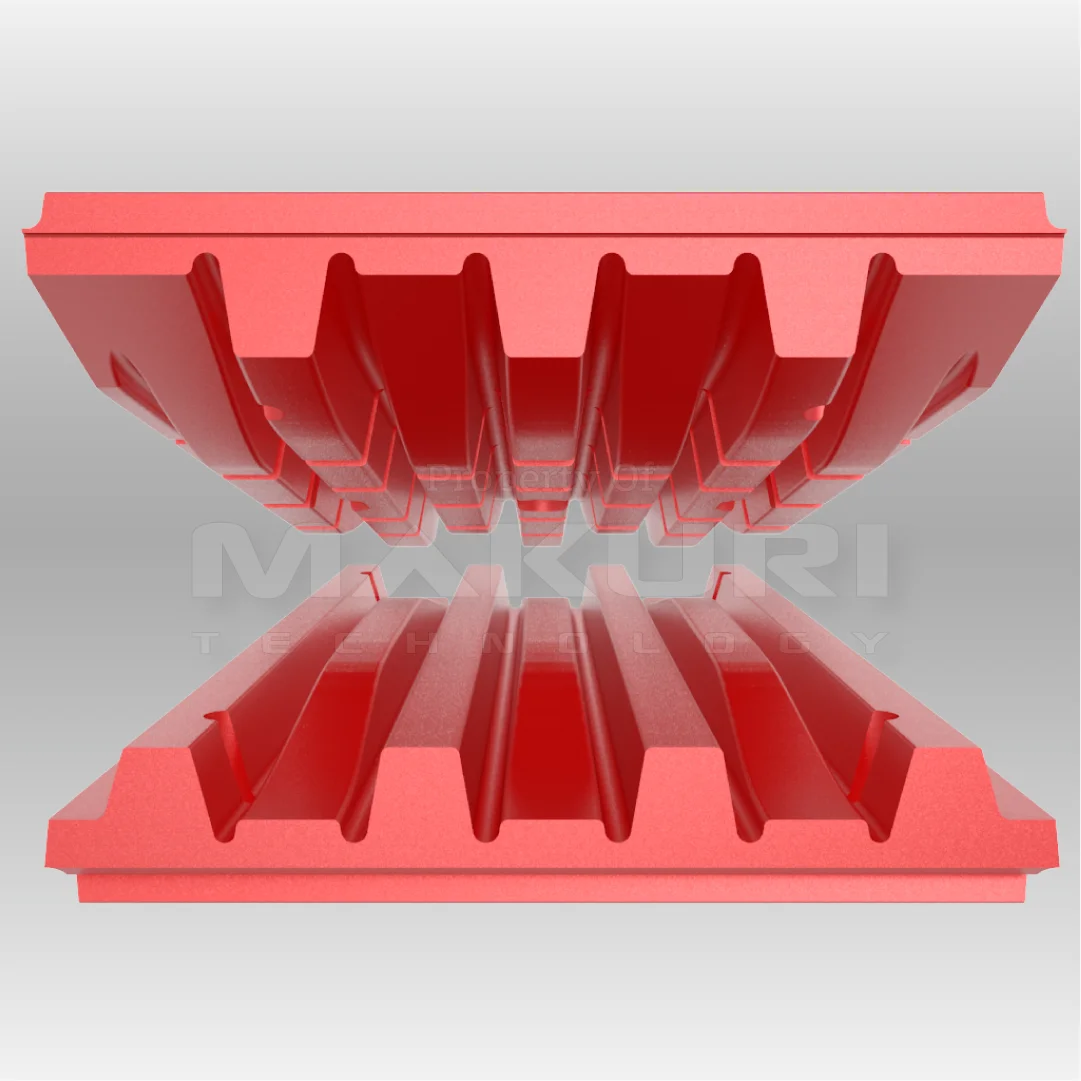

Jaw Crushers

Typical Problems

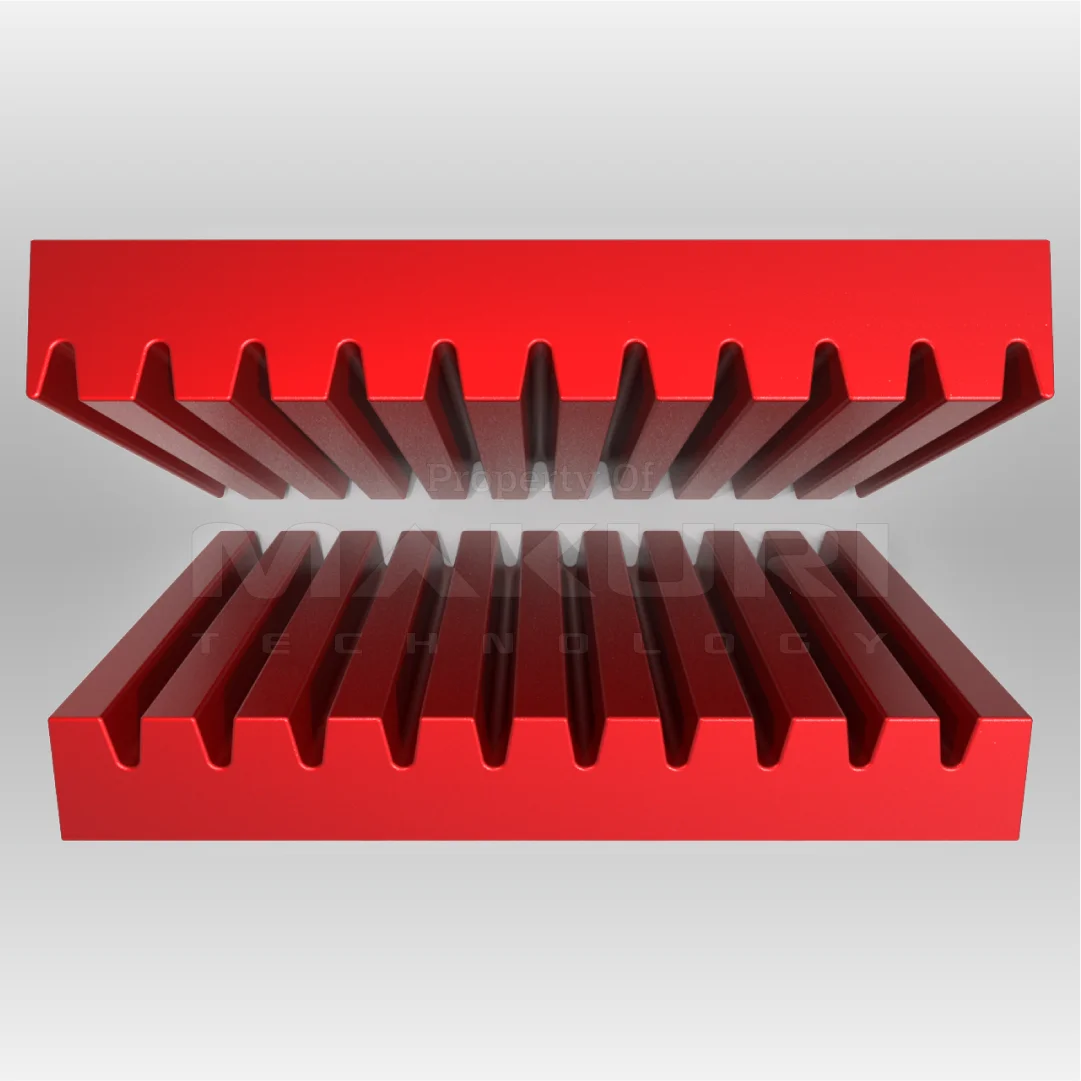

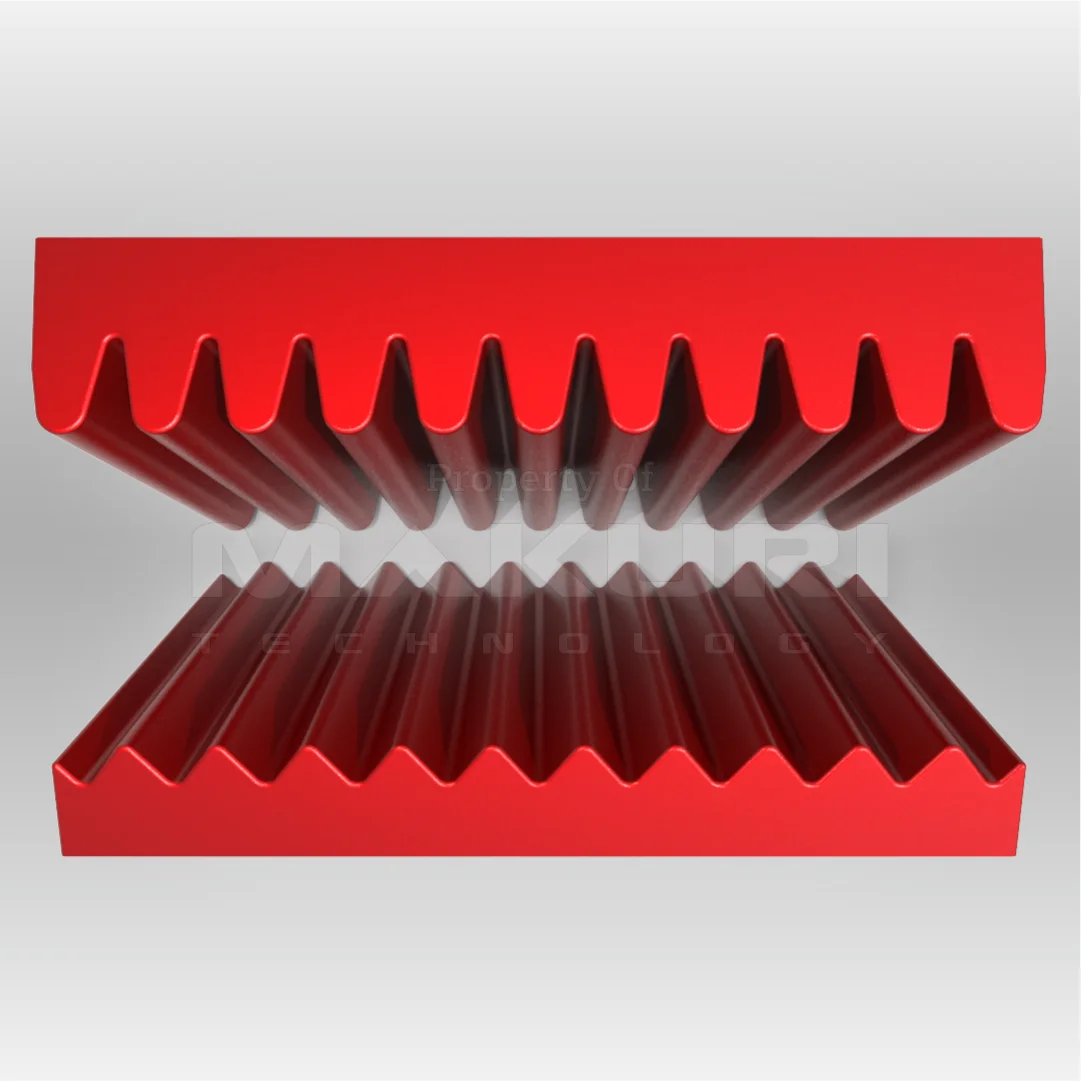

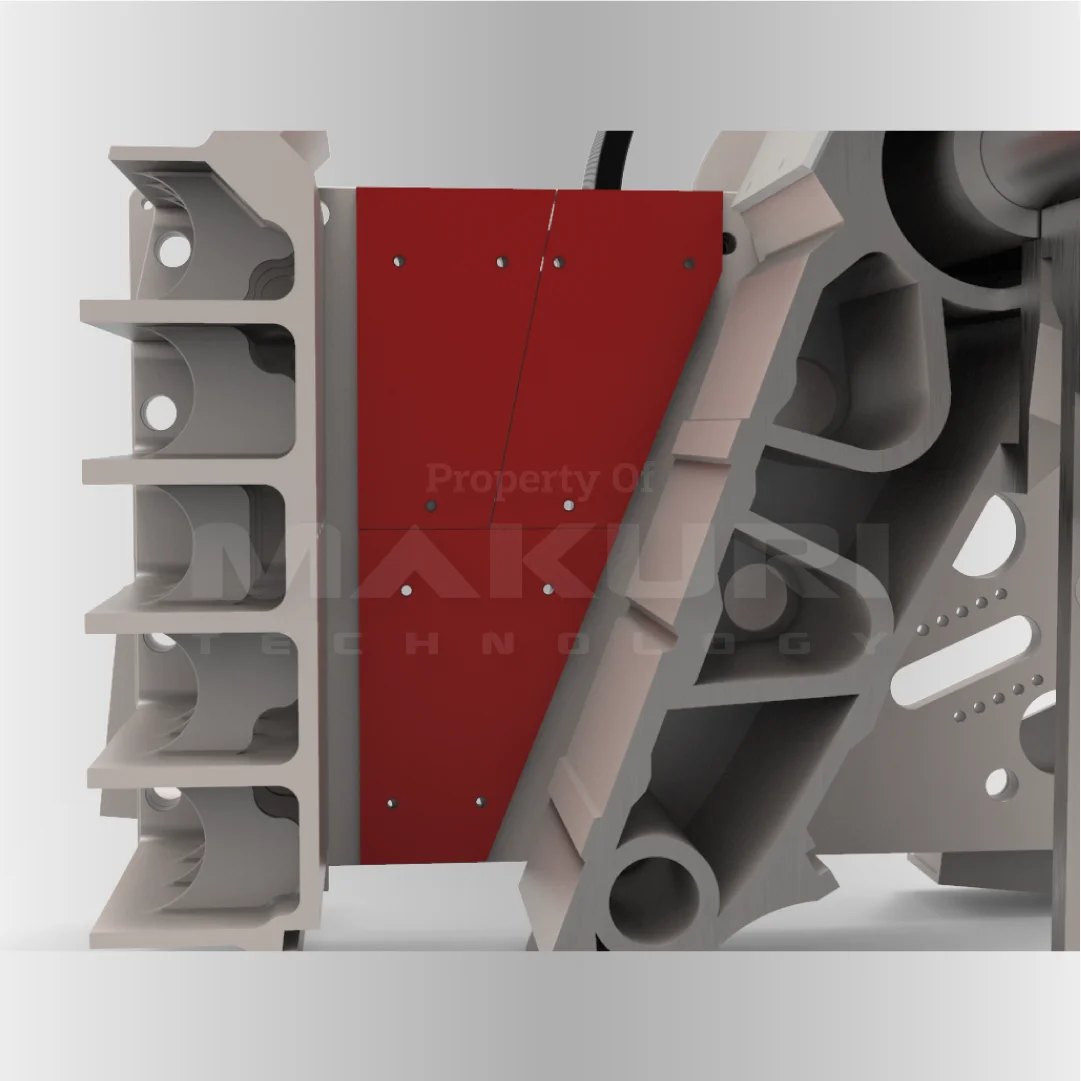

- Jaw liners only wear at the bottom of the fixed jaw & require replacement

- Using 2 fixed jaws for one swing jaw

- Cheek plates don’t last the full jaw life

- Slabby crushed product blocking downstream crushers or SAG mill feed chutes

- Insufficient liner life

- Localised wear at the lower end of the chamber, leading to:

– Inability to maintain CSS

– Poor liner material utilisation - High carbon footprint thru poor liner utilisation

- Safety concerns when changing liners

Makuri Solutions

Longer life liners with better tpoh and psd and safer and easier relines

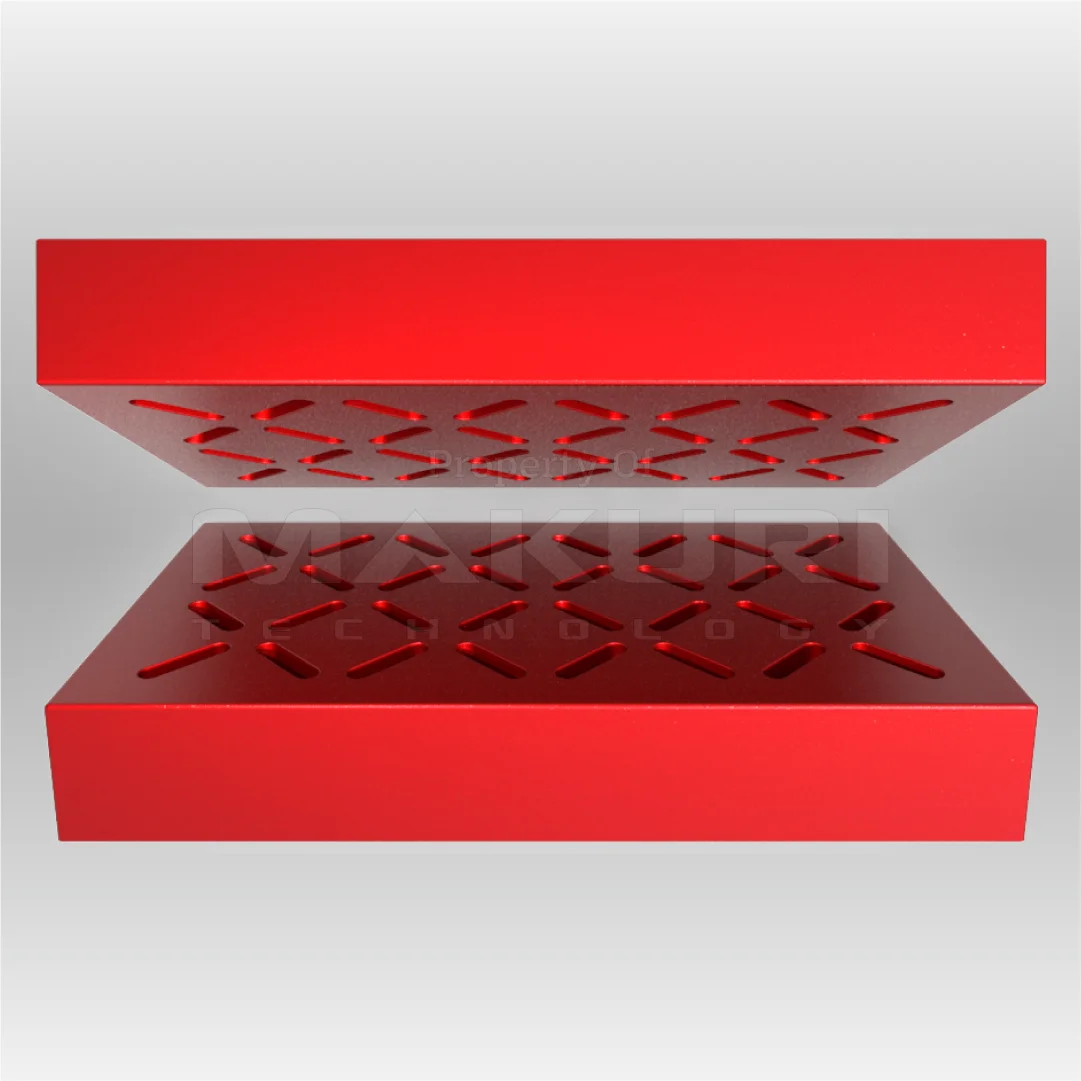

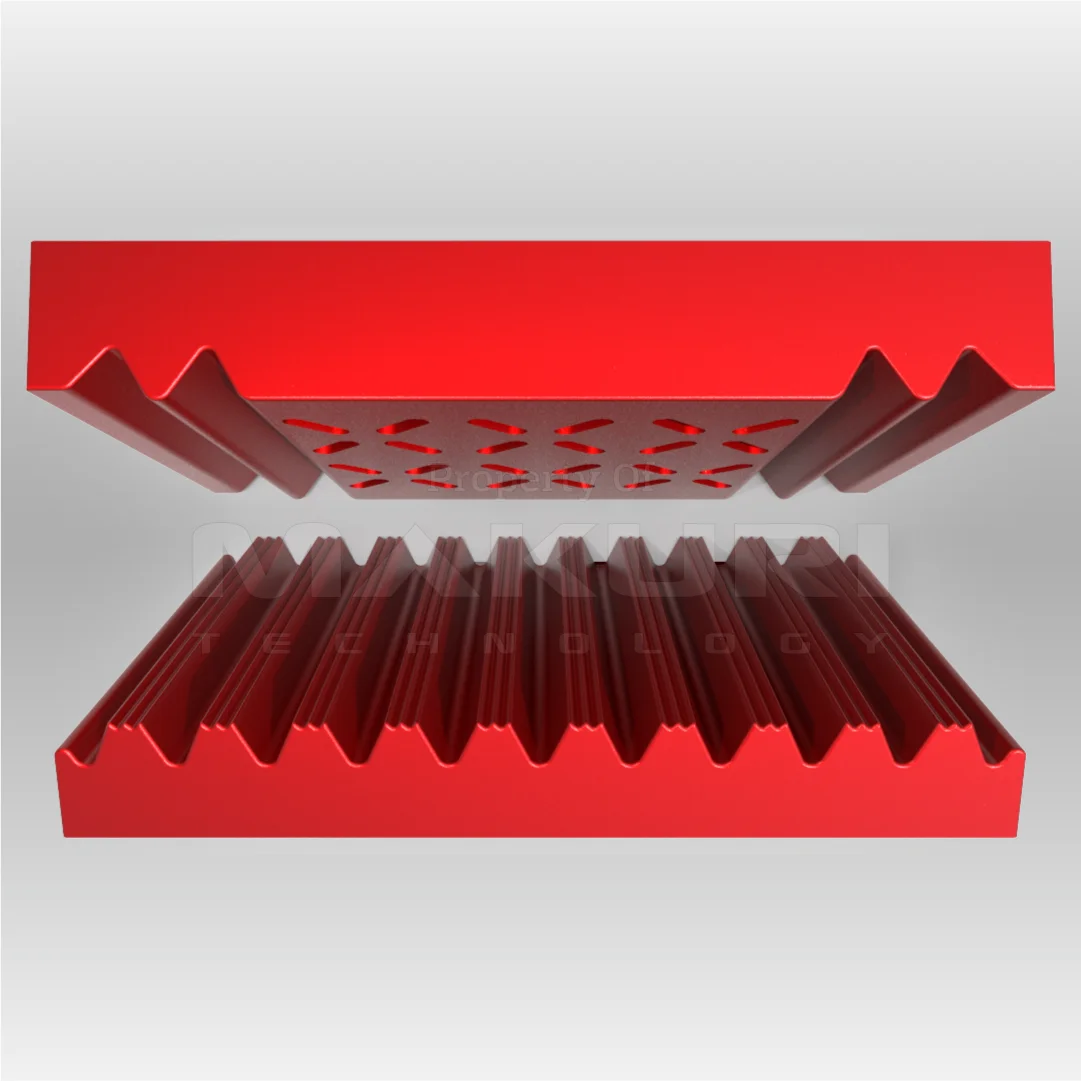

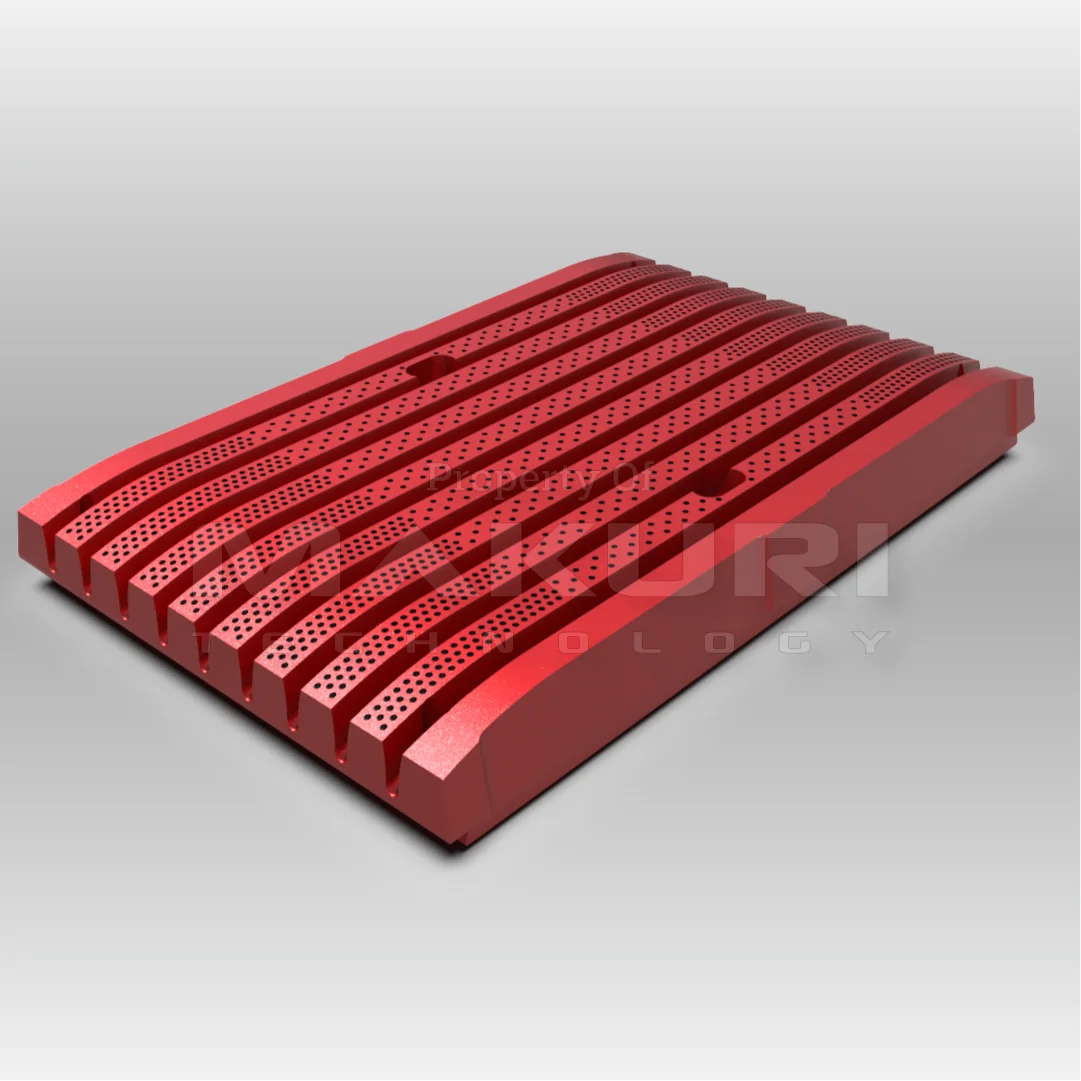

A lack of attention to proper jaw design by OEMs results in poor product shape and high steel usage on jaw crushers, although this is easily resolved with the correct design. In some cases, we have seen jaw liners requiring replacement after only removing 5-10% of their initial mass, resulting in a large amount of wastage and excessive liner cost.

Simply selecting a new tooth profile is generally not enough to resolve these issues, and a more comprehensive review of the operation is required to meet increased operational demands of better tonnes / operating hour (tpoh) and lower product size distribution (psd).

By utilising the Makuri proprietary Intelligent Design™ processes, we are able to supply the right design and right materials that will ensure Makuri can guarantee a lower TCO and provide greater sustainability to our industry.

Using our safe lifting tools reduces downtime and risk when doing liner changes.

We understand crushing better than most. Contact us to see how we can optimise your primary jaw crushing to improve overall plant throughput, maximise asset utilisation and lower carbon footprint.