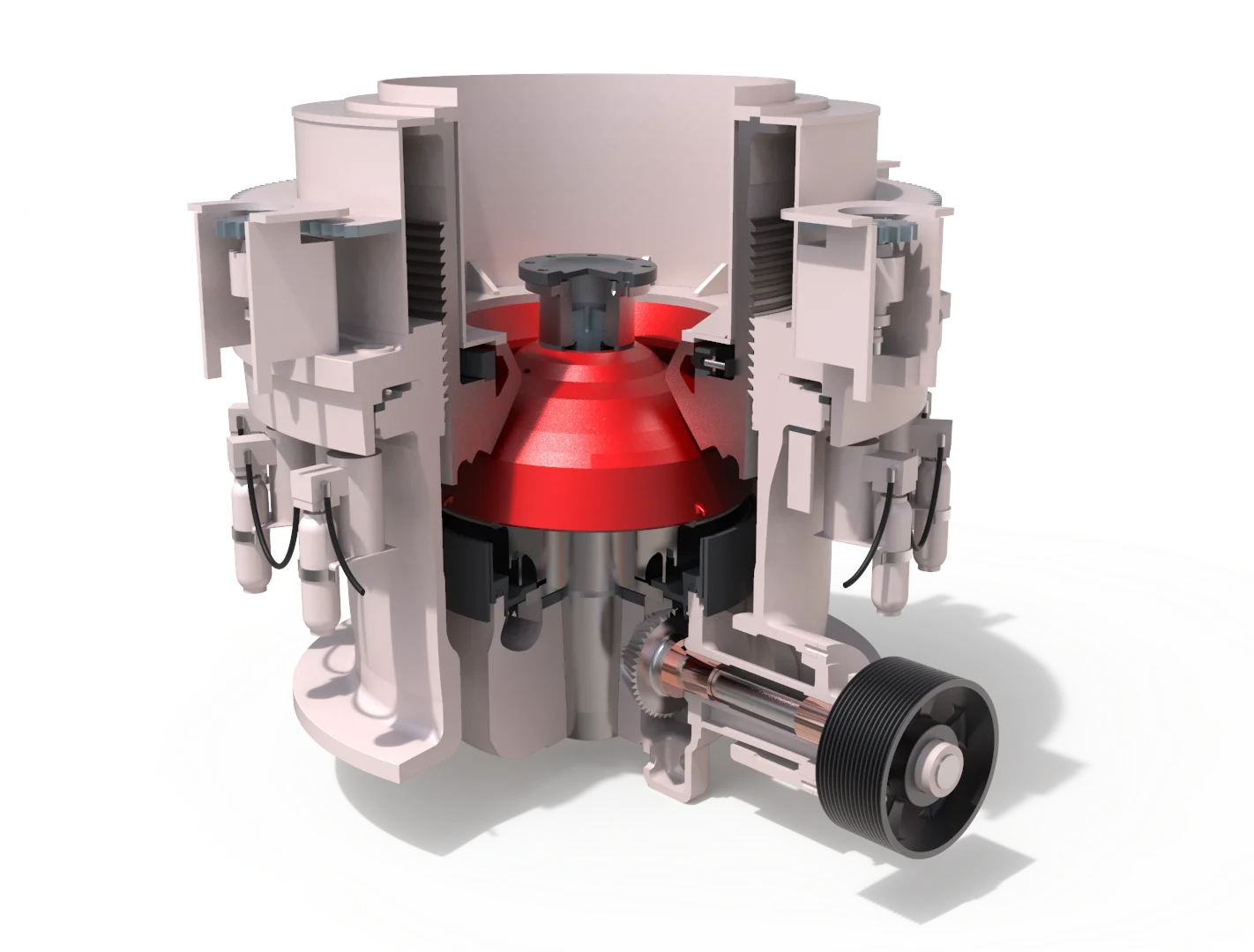

Cone crushers are widely used in the mining industries to crush hard and abrasive materials by compressing them creating a finer and more uniform products.

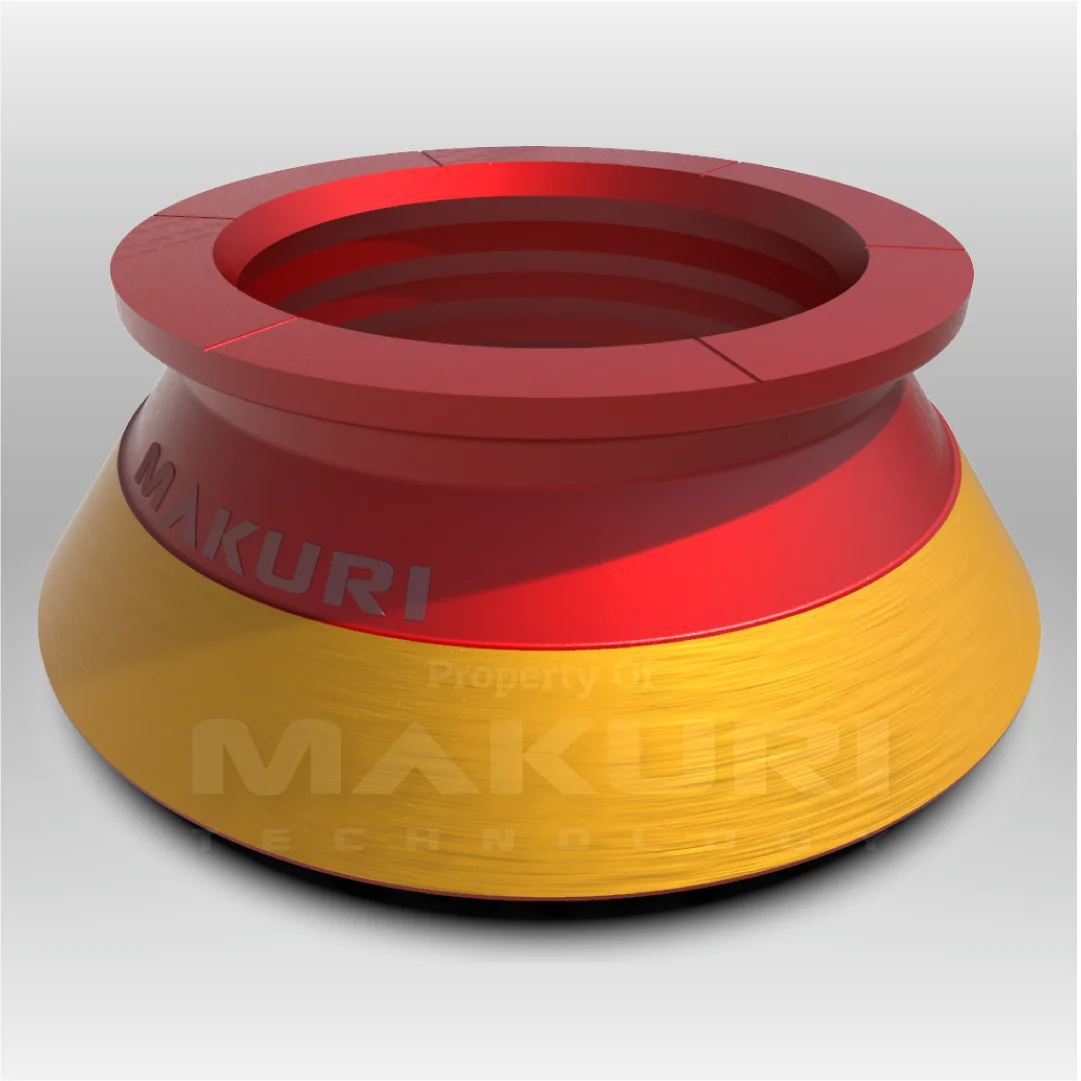

Makuri provides real solutions to the challenges of optimising cone crushers that go above and beyond the typical OEM offerings. Look at each application to see how see how we can best help here.

Secondary Crushers

Tertiary Crushers

Pebble Crushers

Secondary Crushers

Inconsistent primary crusher discharge sizing and associated poor/ incorrect screening, makes for inconsistent feed and sizing to a secondary crusher and as such a challenge to optimise.

Typical Problems

- Blockages due to inability to handle slabby and/or large feed

- Unable to maintain sufficient feed opening as liners wear

- High power draw

- Unable to achieve target gap setting

- Unexpected liner failures

- Uneven wear between bowl and mantle liners

- Excessive wear at the bottom of the chamber

- Cracking heads

- Unplanned shutdowns to change mainframe liners and arm guards —life doesn’t match main liners

- High carbon footprint thru poor liner utilisation

Tertiary Crushers

Increasingly smaller feed material & smaller crushed product sizing requirements present a range of challenges that are normally not well addressed by OEMs.

Typical Problems

- Tramping due to excess fine material in the chamber

- Unable to achieve the target gap within power limitations

- Lost production rate towards end of liner life

- Unusual wear behaviour due to incorrect liner selection

- Unable to achieve a choke-fed condition

- These will not be resolved by simply making thicker liners or changing material grades

- High carbon footprint thru poor liner utilisation

Pebble Crushers

The hardest crushing duty on a mine site is always the pebble crushers. Mill pebbles are the now rounded hard remains of normal ROM feed and typically also contain wet sticky fines, mill balls and ball fragments. These cause a huge and very difficult to manage range of operational and maintenance issues.

Typical Problems

- Unable to achieve and maintain target CSS over the full life of the liners

- Poor availability due to planning based on unpredictable liner life, leading to overly conservative shutdown plans

- Unplanned maintenance due to liner and machine failures

- Poor utilization due to tramp metal detections and low bin levels

- Excessive liner failures due to mill ball damage

- Poor power utilization due to poor cavity profiles over full life of the liners

- Often operating in a ring bounce / bowl flutter condition due to poor cavity profiles

- Operators running machines at a gap setting tighter than the machine is able to handle

- High carbon footprint thru poor liner utilisation