Singapore – April 1 2023 As part of our continous Research & Development commitment, The Makuri Group Introduces the next generation of apron feeder pan technology.

At Makuri Technology, we understand the challenges our customers facing in the process plant sector of mining industries.

Inside Makuri Technology’s intelligent design™ process, we focused on developing and applying new and proprietary processes to allow for our customer to significantly reduce TCO and also increase mining sustainability.

One of the problems that we identifies from apron feeder pans are :

- Excessive wear around bolt holes

- Bolt heads wearing off long before pans were due for replacement

- Bolts being replaced after six months, while pan life was 12 months

The Makuri Solutions

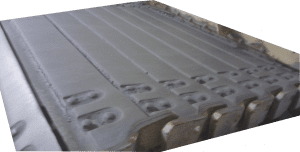

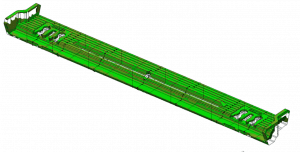

Our apron feeder pan is made of high-strength, abrasion-resistant steel, providing exceptional wear life and reducing maintenance costs. And this is significantly improved by:

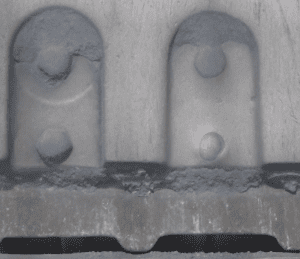

- White iron inserts placed around bolt holes to reduce wear rates

- Modified profile to reduce material flow through recess

- Ridged surface reduces material velocities on discharge to increase overall life

- Grouser bar design further reduces discharge velocity & allows material to flow past front face of pan assembly

The Results

The previous apron feeder pan life usually around 6 – 12 months, and now we achieve as follow:

- After 7 months in operation, almost zero measurable wear to any part of the pan

- No visible damage to bolt heads

- Conservative life estimate now 3-4 years

- Reported better expert control loop responses most likely due to less slippage upon speed change

We are proud with our latest innovation and the achievement reached and will continue to strive following our intelligent design™ core values to not only apron feeder pans, but for all of our product range.

Contact us and join our partner program so you can also become the first to benefit from our newest technology and innovation.