What is an Apron Feeder?

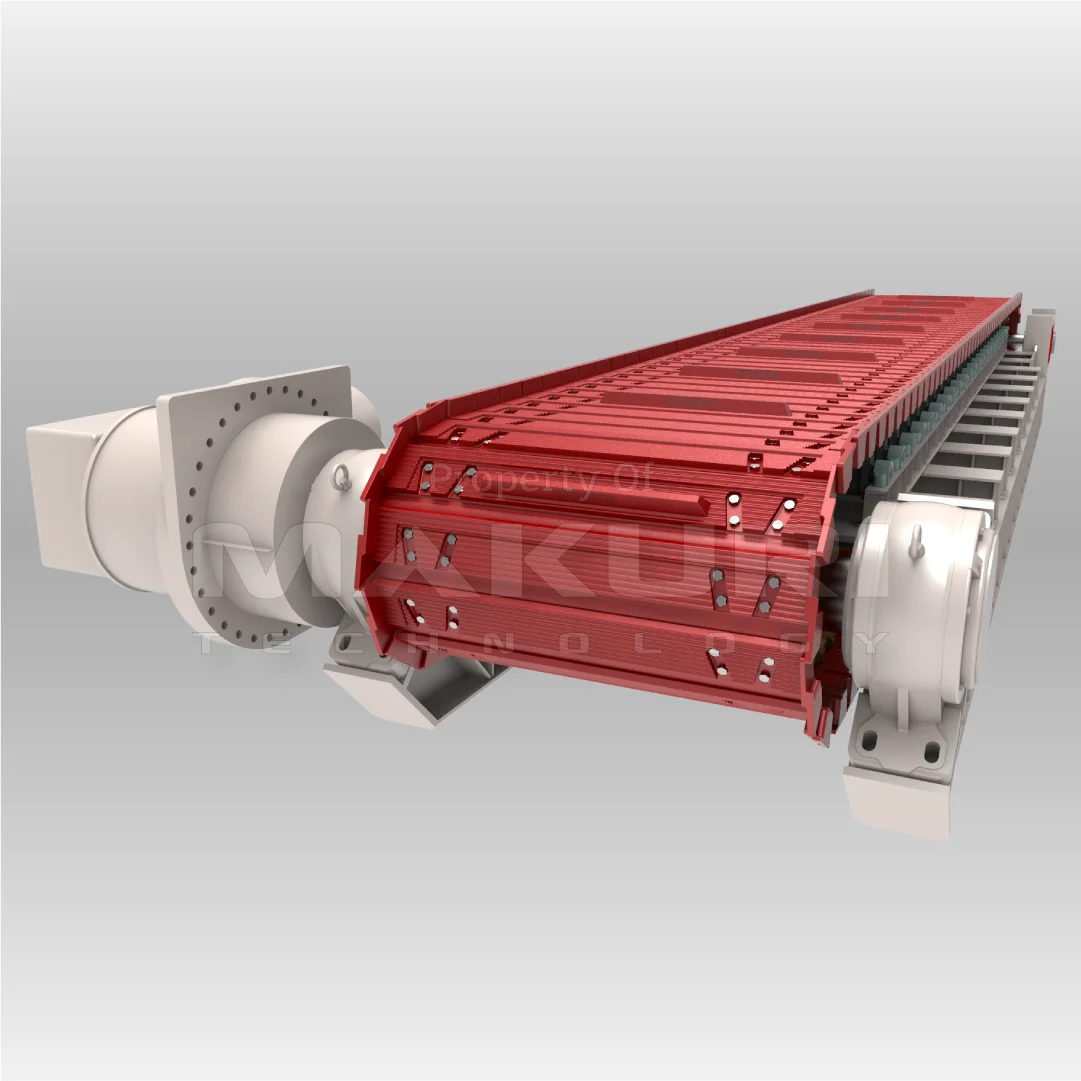

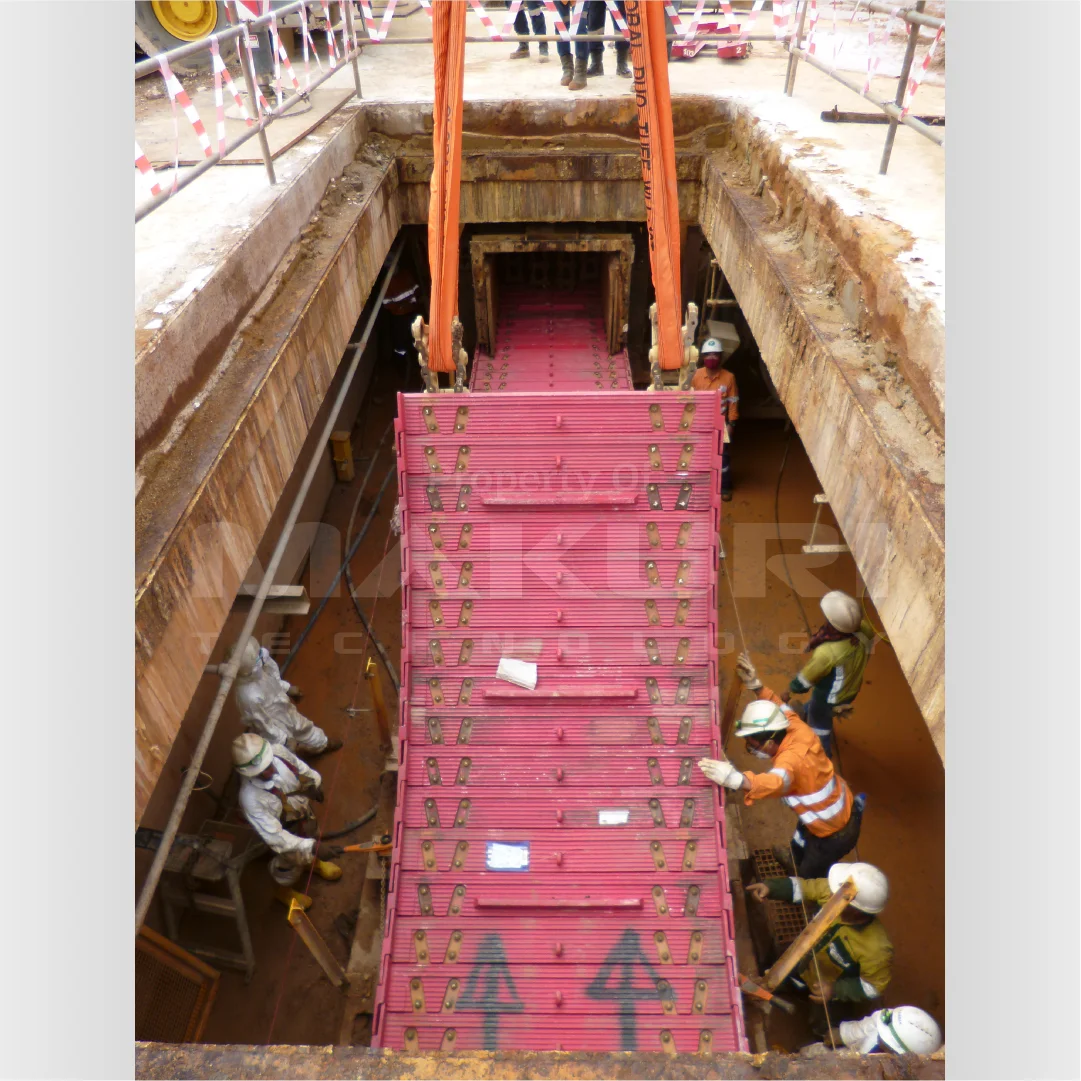

Apron feeders are commonly used in industries such as mining and aggregate processing, where they are used to handle materials such as ores, coal, and rock. An apron feeder is a type of material handling equipment used to transport large, lumpy, or abrasive materials from a storage bin or hopper to a crusher, conveyor belt, or other processing equipment.

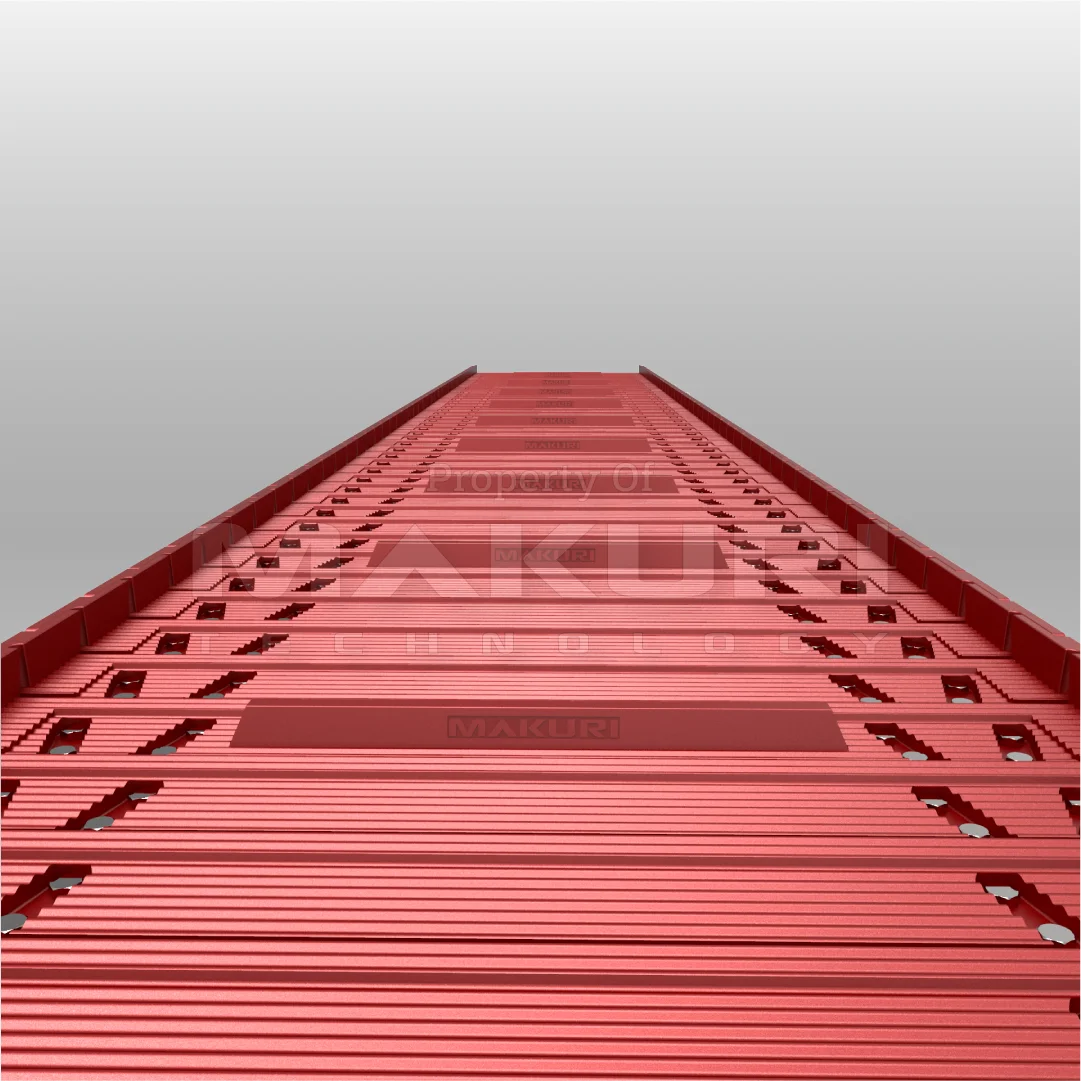

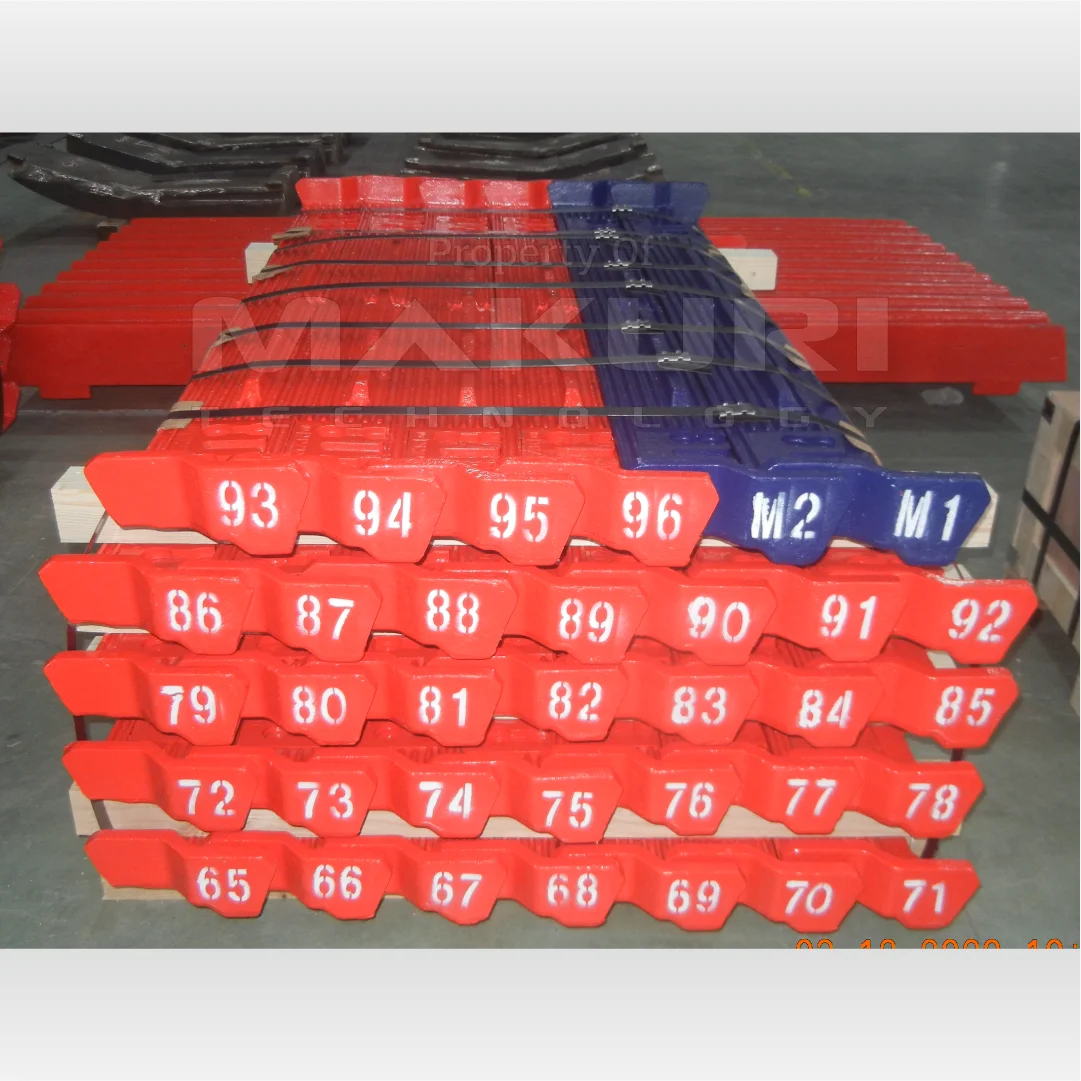

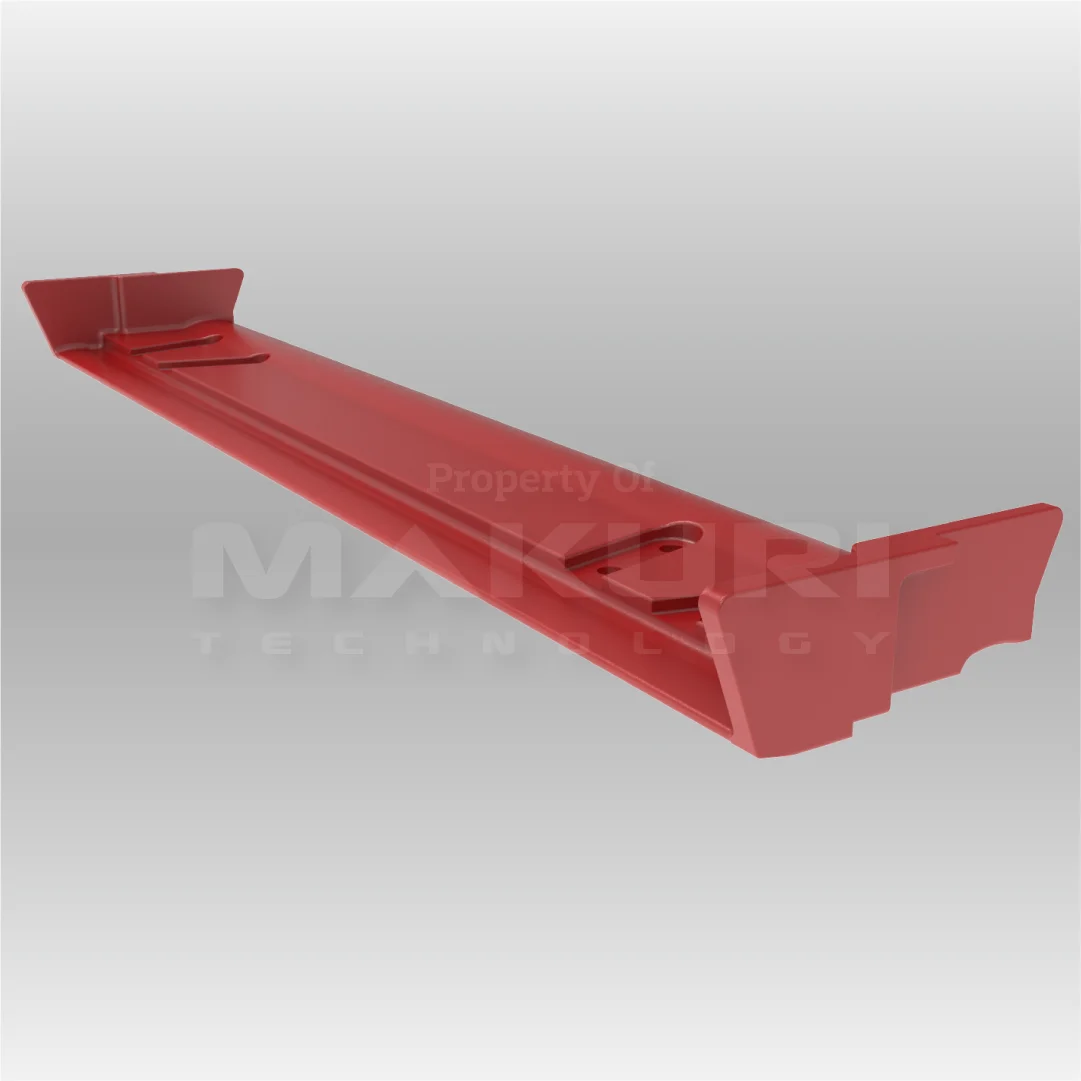

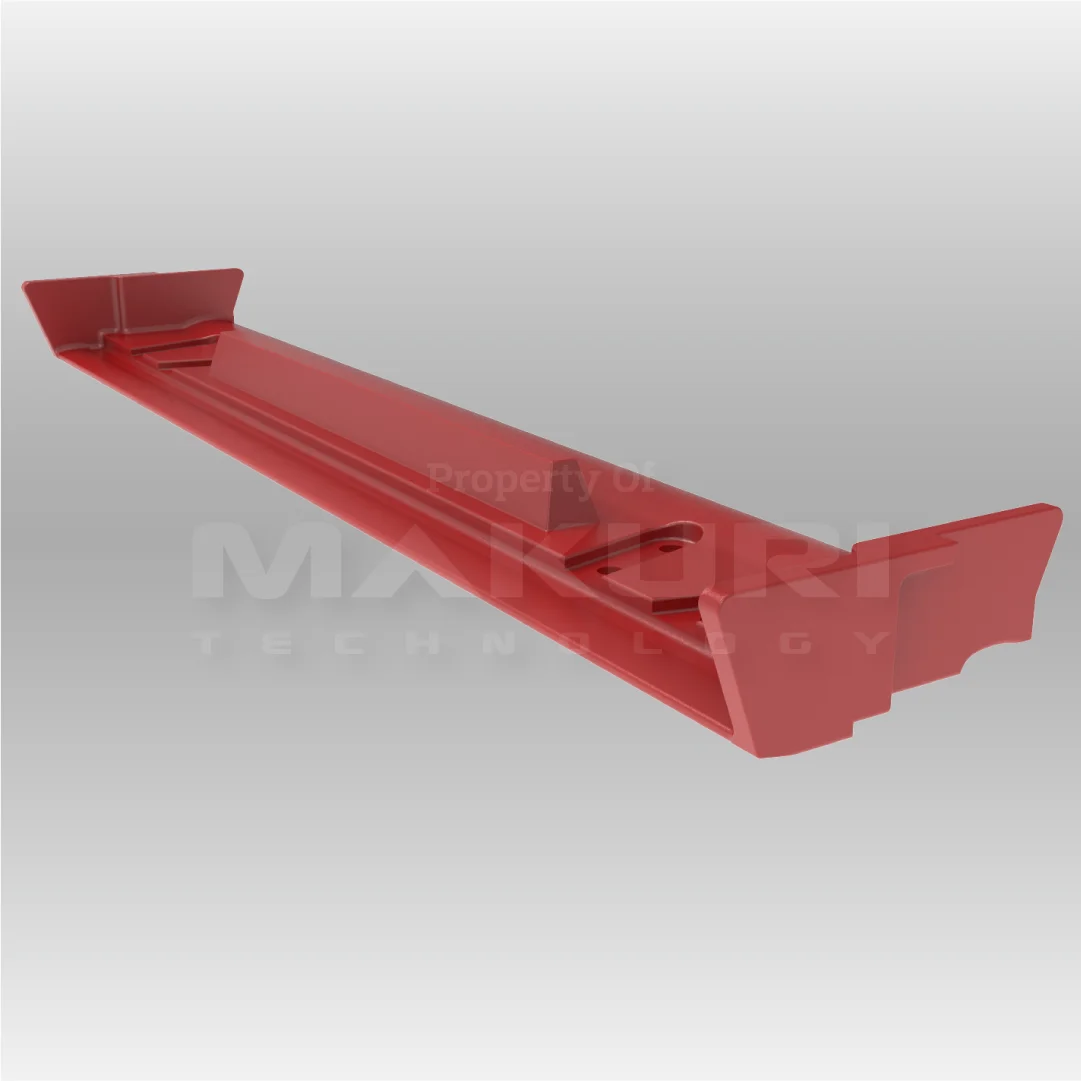

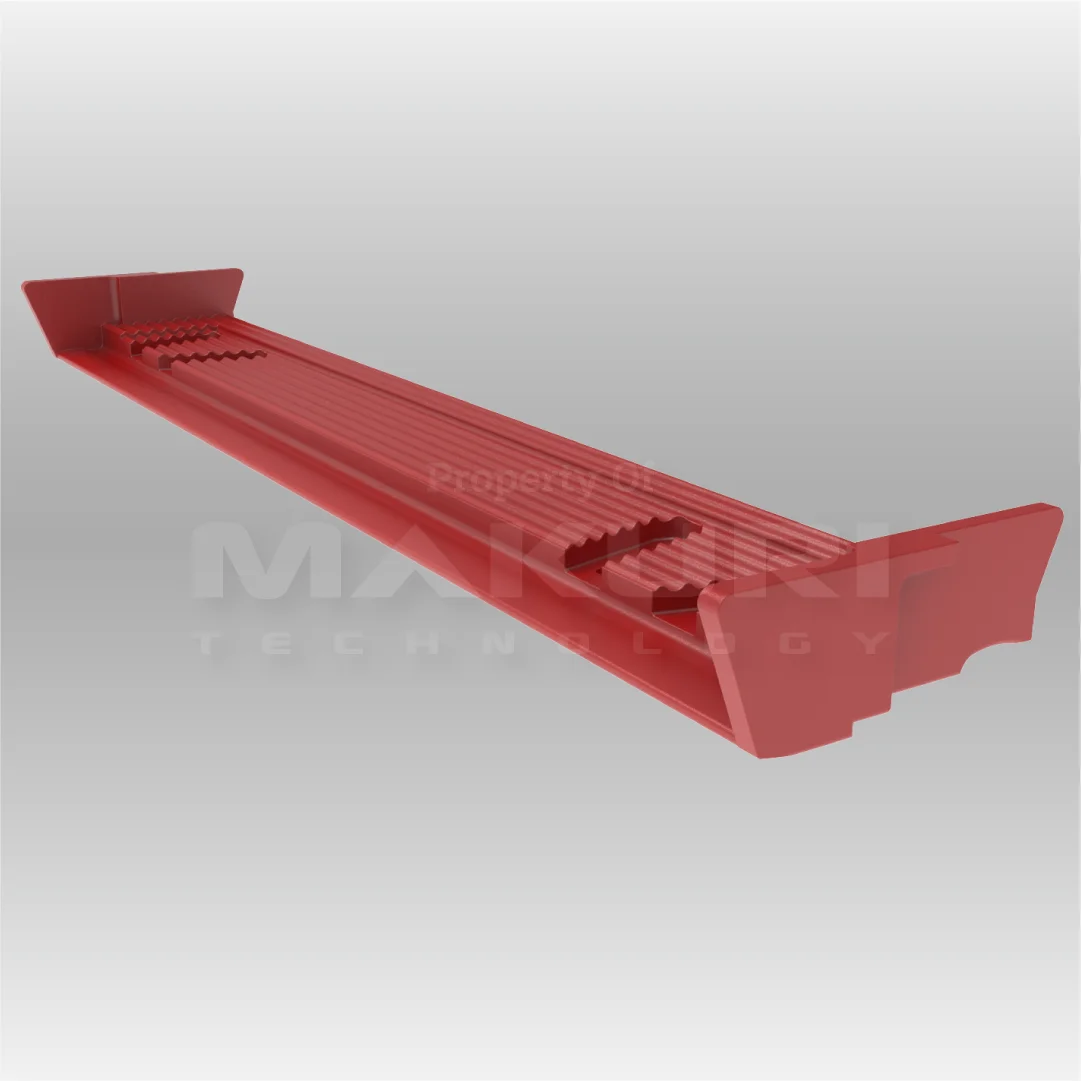

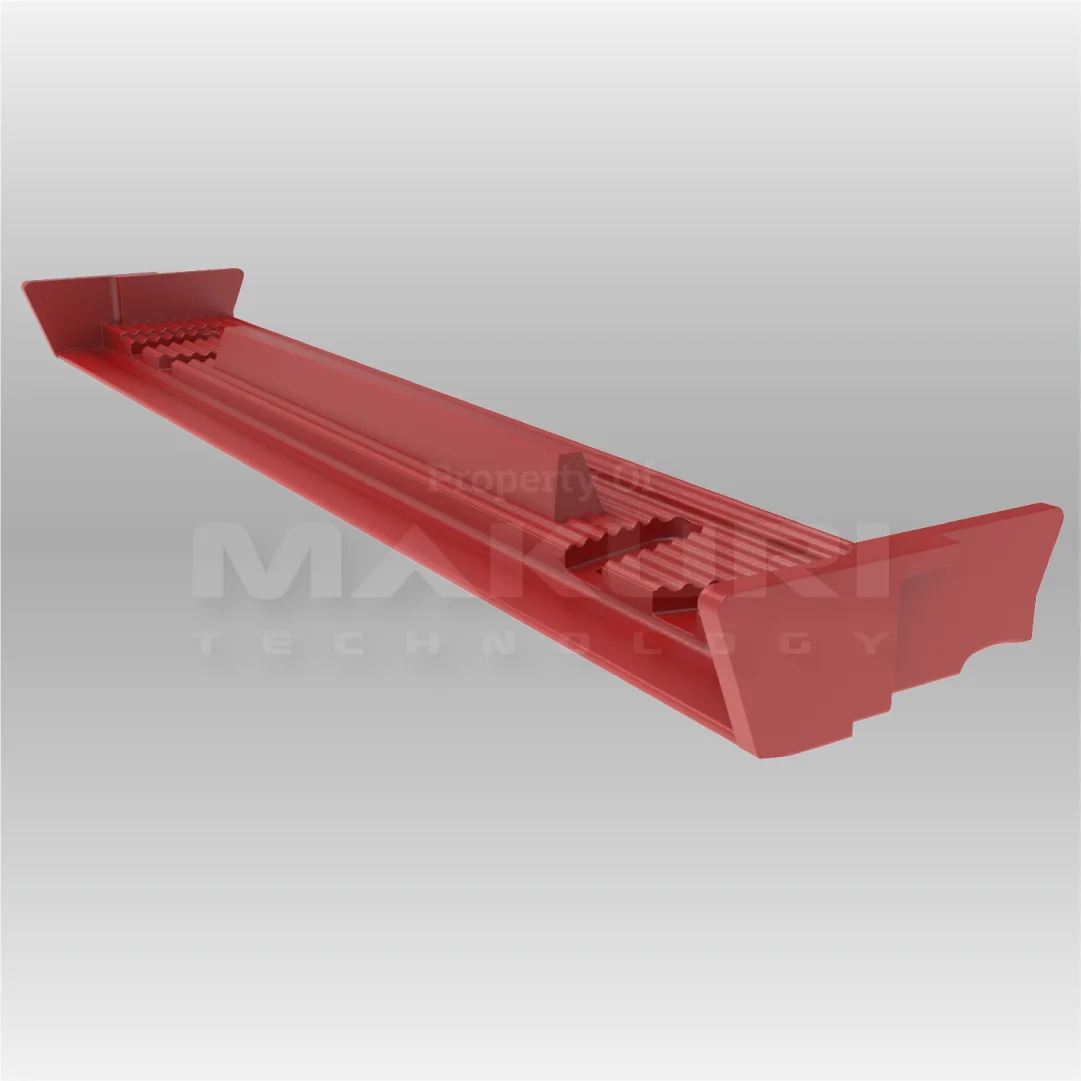

Apron Feeders has had little to no technology development since the design and manufacturing methods for apron feeder pans, or flights as they are sometimes called, were developed many decades ago to run on, off the shelf, standard dozer chains and drive tumblers.