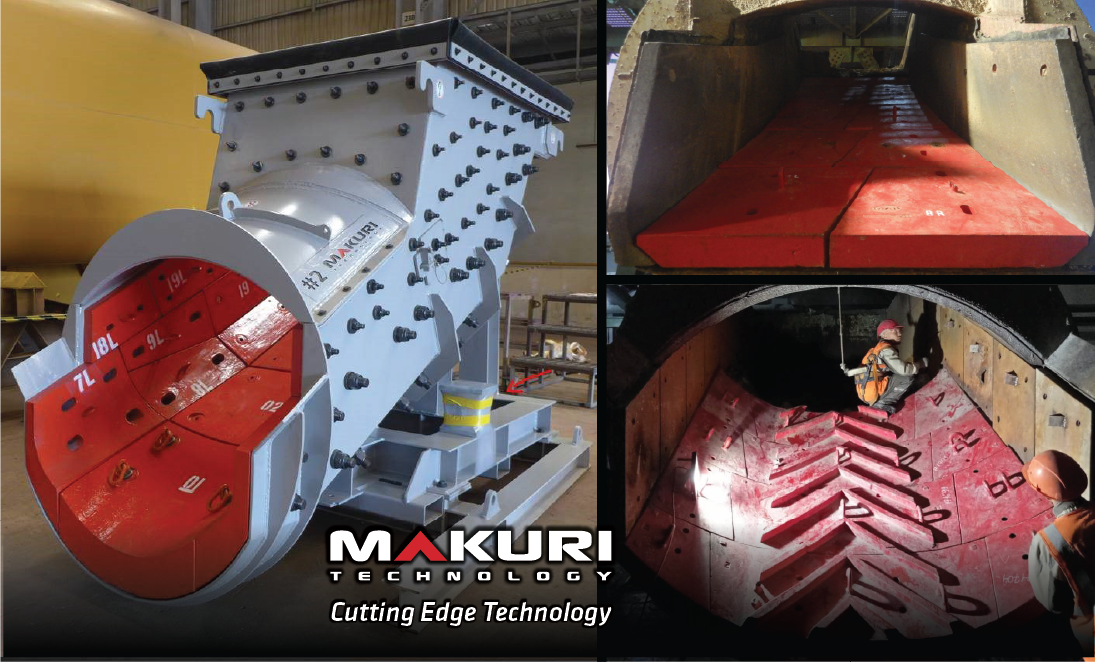

MAKURI continues to drive improvements in equipment reliability and performance with the successful implementation of our XAB3 liner on a SAG mill feed chute.

The Challenge

The site was facing rapid wear issues, with OEM liners lasting only four weeks. This frequent replacement cycle led to increased downtime, maintenance workload, and operational costs. The customer reached out to MAKURI seeking a liner solution with extended service life to improve mill availability and reduce shutdown frequency.

The Solution

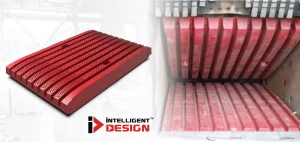

MAKURI supplied the XAB3 liner, material engineered specifically for high-impact, high-wear applications such as SAG mill feed chutes. Utilizing advanced materials and optimized design, the XAB3 provides superior wear resistance and fitment accuracy, ensuring both performance and safety during operation.

The Results

Service life extended from 4 weeks to 16 weeks — a 4× improvement over the OEM liner

Minor shutdown intervals increased from every 4 weeks to every 8 weeks

Significant reduction in downtime and maintenance costs

Improved reliability and operational efficiency

This project demonstrates MAKURI’s commitment to delivering practical, proven, and high-performance wear solutions.

MAKURI has also achieved similar success stories in Alaska, Kazakhstan, and Africa, where the XAB 3 liner and other engineered solutions have delivered outstanding improvements in wear life and productivity across different operating conditions.