A Smarter Fastening Solution for Safer, Faster, and Stronger Wear Liner Installations

MAK-Lok™ Single-Sided Bolting Systems from Makuri offers a high-performance alternative to conventional fastening methods. Fully compatible with existing chute wall with no additional modification. MAK-Lok™ provides easy upgrades without major modifications—delivering exceptional strength, safety, and ease of use across various plant applications.

Whether you’re working with thick or thin wear plates, MAK-Lok™ adapts to your needs through two core styles:

Type-T for thicker plates, commonly used in our XAB1 liner

Type-S Welded Inserts for thinner plates, commonly used in our XAB8 & XAB9 liner

Both options seamlessly integrate with Makuri’s innovative Type R rail system, allowing fast, low-disruption retrofits to existing chutes.

-

Type T

-

Type S

-

Type R

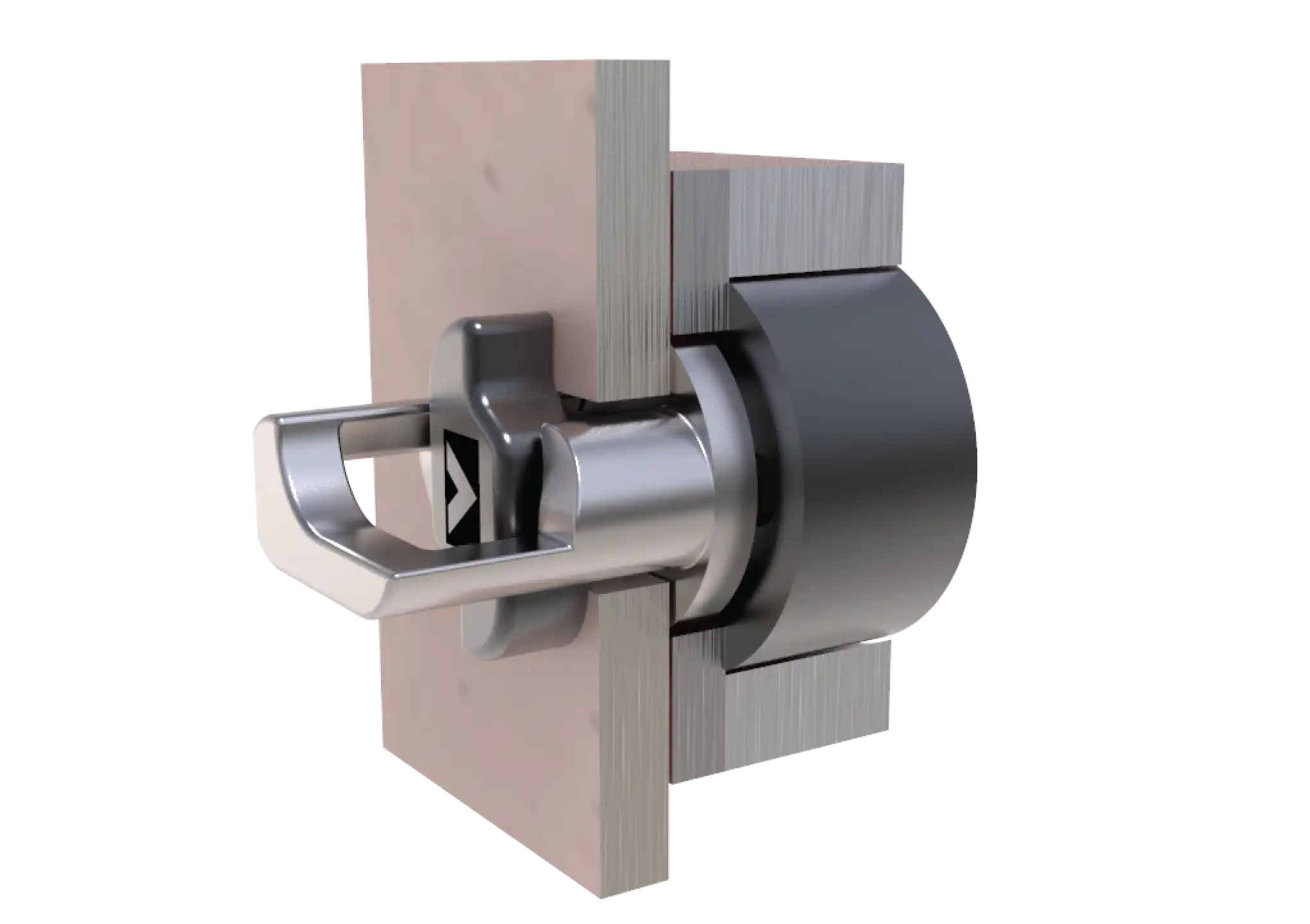

MAK-Lok™ Type T

MAK-Lok™ Type T is designed to use existing slotted hole on the chute used from Metso™ Taper T.

The MAK-Lok™ Type T is the ultimate solution for securing thicker wear plates in high-impact, high-wear environments—offering unmatched strength, durability, and ease of use.

Designed for Demanding Conditions

Built to handle tough mining and processing applications, the Type-T assembly is engineered for wear plates 24mm thick and above (Optimally using our XAB 1 & XAB 3 wear liner), making it ideal for heavy-duty liners that demand maximum holding power.

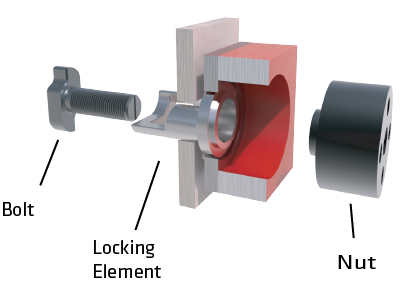

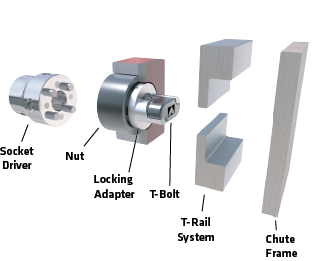

The system includes a nut and bolt assembly pre-installed in a robust locking element. This locking element ensures the bolt head is accurately positioned and securely housed during installation—and remains captured and aligned even when the fastener is removed, simplifying reassembly and reducing part loss.

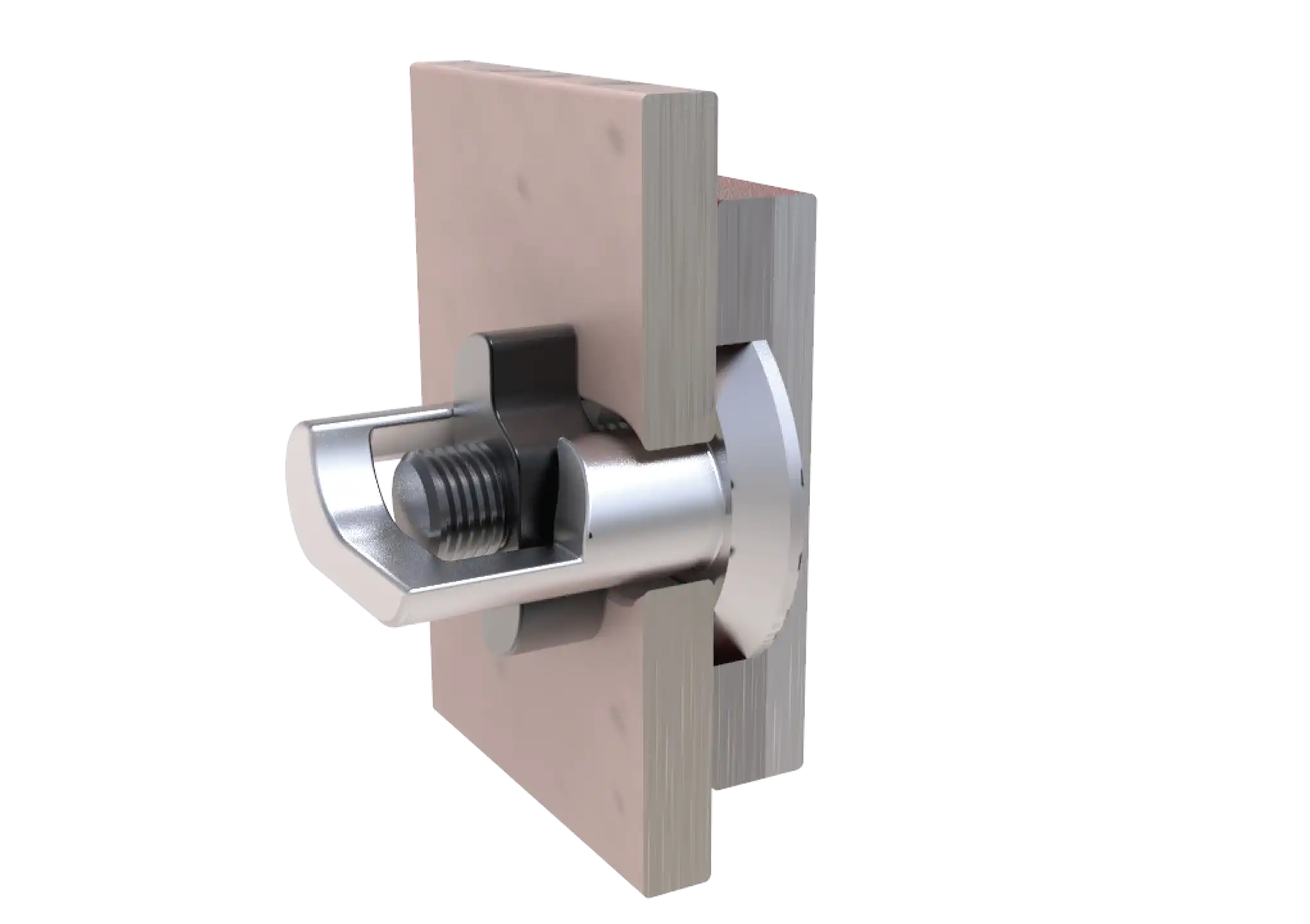

MAK-Lok™ Type S

MAK-Lok™ Type S is also designed to use existing slotted hole on the chute used from Metso™ Taper T.

When space is tight and liner thickness is limited, MAK-Lok™ Type S delivers the perfect fastening solution. Engineered for thinner wear plates and bimetallic liners (optimally using our XAB 8 & XAB 9 Wear plate), this welded-in design provides exceptional holding strength, reliability, and safety—all from the wear side only.

Optimized for Thin Plates and Compact Installations

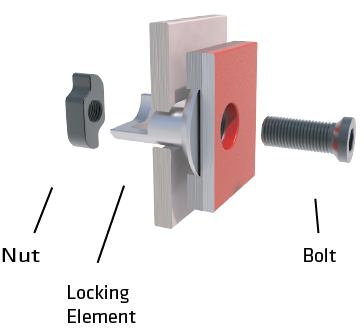

The Type-S system is a low-profile, welded design that integrates directly into the backing plate of the liner. Ideal for liners under 24mm or bimetallic wear blocks, it maintains all the benefits of MAK-Lok’s single-sided operation—without compromising on strength or safety.

Instead of a bolt head, the Type S uses a profiled nut on the back side and a socket-head bolt inserted from the wear side, securely tightening into the integrated locking insert.

MAK-Lok™ Type R - Rail System

The Type R Rail System allows you to convert conventional through-bolted chute designs to a fully compatible MAK-Lok™ single-sided system—without the need for modifications. It’s the ideal solution for operations seeking to improve safety and efficiency without costly downtime or fabrication work.

Rails are mounted inside the chute and serve as anchor points for MAK-Lok™ Type T or Type S assemblies, allowing wear liners to be securely fastened using our patented single-sided locking technology.

How It Works

The patented MAK-Lok™ systems uses a unique locking element that ensures proper alignment and secure clamping from the wear side only—no rear access needed.

- During tightening, the bolt is guided into place by the locking mechanism, ensuring precise fit and maximum hold.

- During removal, the bolt head returns to its original position within the housing, allowing for quick and easy disassembly, with all components retained in the assembly.