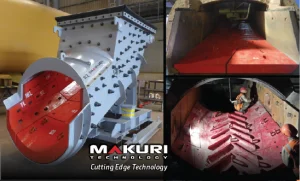

When a hard rock gold mining operation running a single primary Jaw Crusher faced a series of issues, they turned to Makuri Technology to resolve them. Higher costs per tonne and TPOH losses were caused by increasingly harder ores, reducing liner life, plus fitment and dislodgement issues. They partnered with Makuri to develop a fully customised jaw liner solution tailored to their operational and maintenance strategy.

The site was operating an OEM liner system, but the upper and lower fixed and swing life did not align with their shutdown strategy. In addition, the operation required a finer PSD to suit their scalping screen decks and secondary crusher.

Makuri was engaged to engineer a complete solution, including:

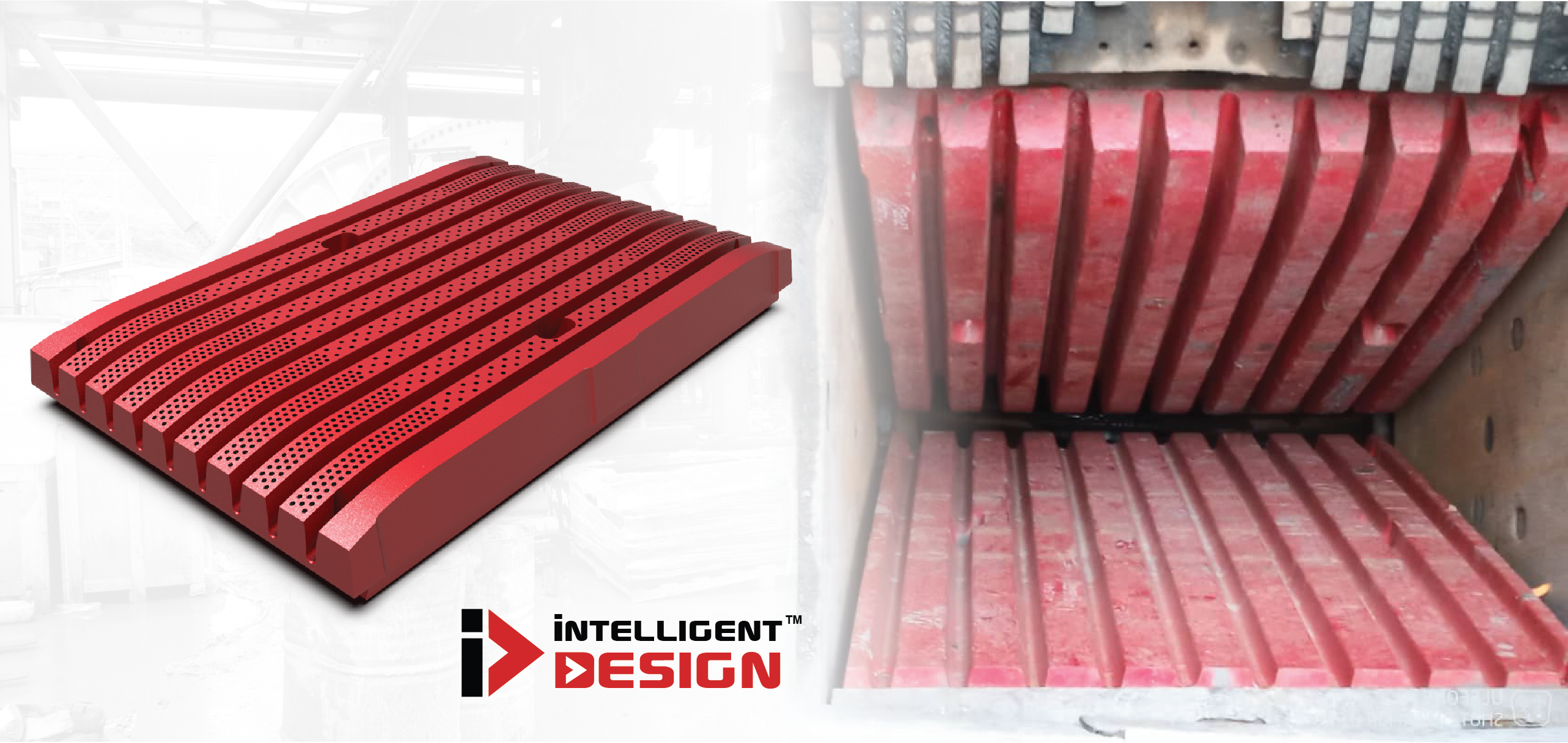

- A single-piece custom jaw profile capable of producing finer material and eliminating the dual-piece configuration

- A custom kidney-bolt arrangement to prevent liner movement and dislodgement

- A minimum 10% life improvement over the existing liner system

- A custom lifting arrangement to simplify installation and maintenance

Using site-wear photos and 3D laser scans, combined with real operational PI data, Makuri developed a high-tooth jaw profile with long-life HARD-Core carbide inserts, optimised insert spacing, and added kidney-nut holes to prevent liner loss from worn or incorrectly installed wedges.

After installation, the results were immediate and measurable:

A control trial using 18% manganese single-piece liners (no carbide inserts) required four changeouts per year and failed to meet maintenance targets — confirming the value of Makuri’s HARD-Core insert design.

The site completed a full ROI assessment:

✅ Payback period: 0.9 years

✅ Profitability index: >15.0

The outcome:

✅ safer lifting, fitment and removal of liners

✅ >40% reduction in liner and labour costs

✅ >13% increase in primary crushing plant operating time

✅ >40% less maintenance interventions

A powerful example of how Makuri’s site-driven engineering, metallurgy expertise, and Intelligent Design™ process deliver real operational value.